Patterson Kelley

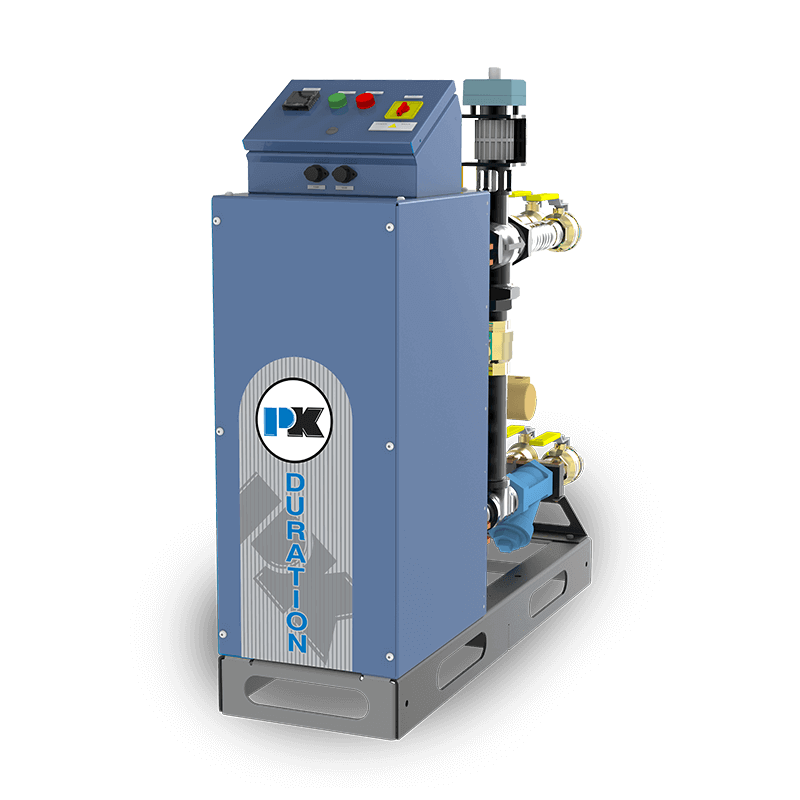

- 800 and 1000 MBTU Input

- Natural Gas Fired

- 128 Gallon Storage

- Instantaneous condensing hot water heater with HLW stamp

- Duplex alloy stainless steel storage tank

August 12, 2019

High-quality design and construction Complete package with only four piping connections High-capacity output ANTICIPATOR® temperature control regulates hot water outlet temperatures ±4F Copper-nickel shell, naval brass […]

December 8, 2021

Recovery Rates (40 Deg F – 140 Deg F) – 0-85 GPM Domestic Water Demand Fully packaged water to water plate and frame heat exchanger system […]

December 8, 2021

800 and 1000 MBTU Input Natural Gas Fired 128 Gallon Storage Instantaneous condensing hot water heater with HLW stamp Duplex alloy stainless steel storage tank

August 12, 2019

Size Range: 300-1050 MBTU Entire package fits in the boiler footprint Domestic water loop is isolated from the boiler loop Precise temperature regulation with no mixing […]

August 12, 2019

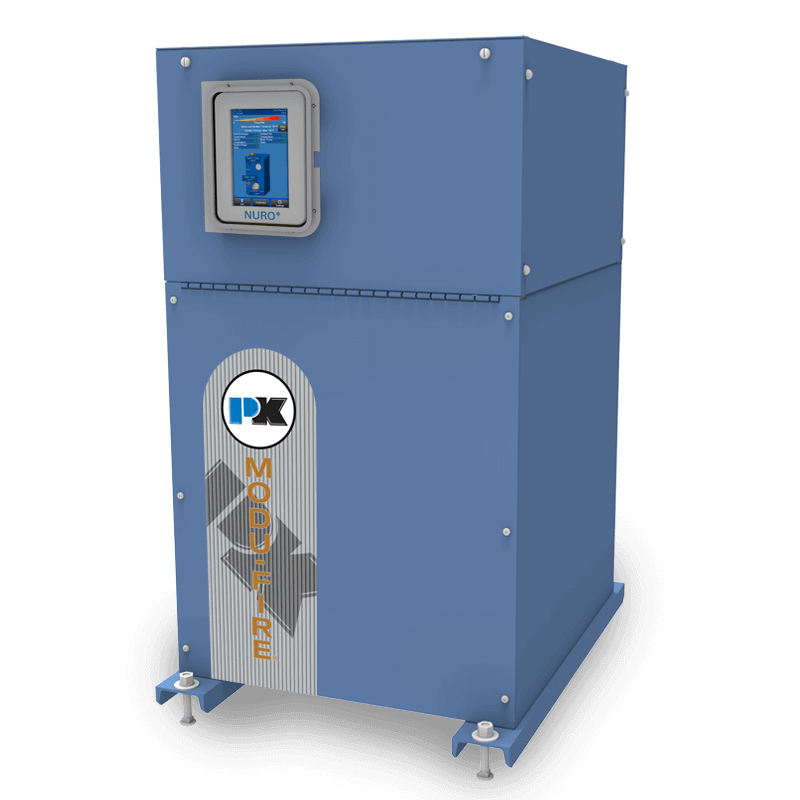

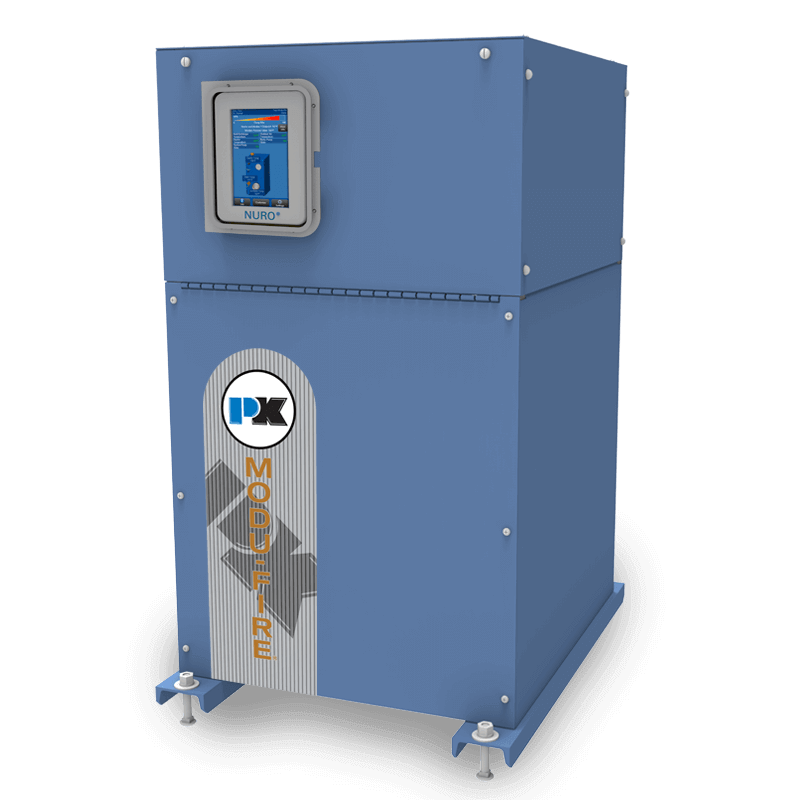

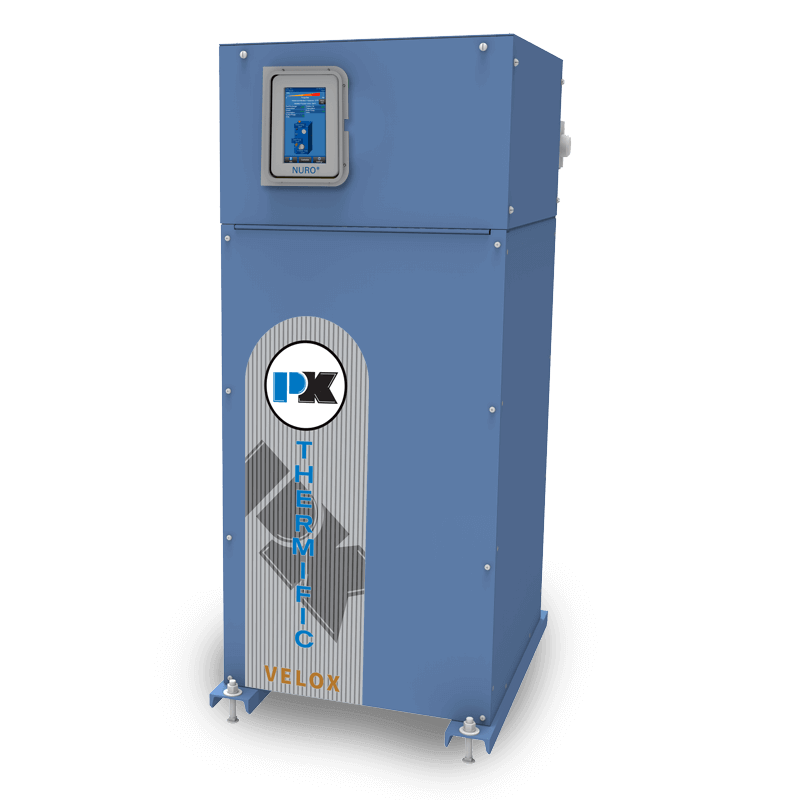

Size Range: 300-4000 MBTU Equipped with the latest touch-screen technology, the NURO™ Touch-Screen Control All-purpose boiler suitable for condensing and non-condensing systems Revolutionary new, fully independent […]

December 8, 2021

Size Range: 750-2000 208-240V/1ph/60HZ Copper finned tube heat exchanger 5:1 turndown can track varying loads Glass lined heads and nickel plated tube sheets Eliminates short cycling […]

August 12, 2019

Size Range: 750-3000 MBTU Small, modular configuration, big output Smooth 5:1 turndown can track varying loads down to 20% of rated capacity Dynamic air density compensation […]

August 12, 2019

Interactive 7” Touch Screen interface or USB mouse/keyboard Set-Up Wizard to walk you through the operational set up parameters Flame safeguard device Lead/lag cascade control w/outdoor […]

December 8, 2021

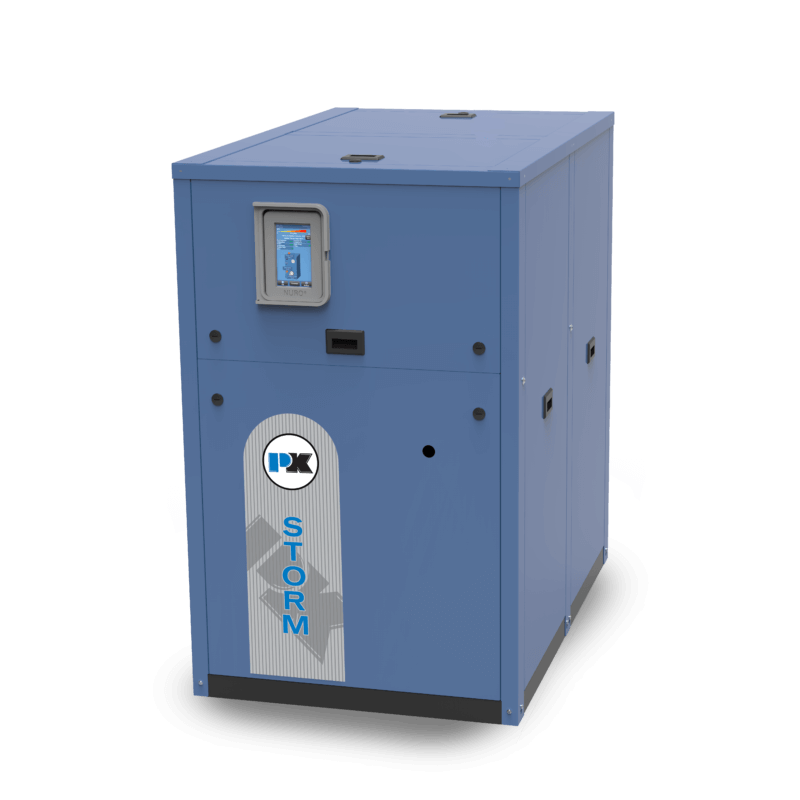

Size Range: 1500-3000 MBTU Up to 96% thermal efficiency 304 Stainless Steel Firetube Design Full Modulation burner with up to 10:1 turndown Ultra-Low NOx Emissions Removable […]

December 8, 2021

Size Range: 650-1000 Up to 7:1 turndown Certified up to 97% efficiency Stainless steel alloys resist corrosive condensation

August 12, 2019

Size Range: 650-4000 MBTU Unique stainless alloys resist corrosive condensation Patented DUET™ Technology Up to 60% smaller than the leading competition Reliable, easy to use NURO® […]

December 8, 2021

Size Range: 650-6000 MBTU Natural Gas fired Up to 97% thermal efficiency 316L Stainless Steel Watertube Design Full Modulation burner with up to 10:1 turndown Cabinet […]

December 8, 2021

Size Range: 750-2000 120V/1ph/60HZ Vertical burner/heat exchanger design Copper finned tube heat exchanger Natural Gas or Liquid Propan

August 12, 2019

Size Range: 750-2000 MBTU Completely packaged design Compact/modular design allows multiple units to be installed in tandem Vertical burner/heat exchanger design Unique integral finned copper water […]

August 12, 2019

Size Range: 700-2000 MBTU Optional storage tank can complete the package Compact/modular design allows multiple units to be installed in tandem Vertical burner/heat exchanger design Unique […]