Piping Solutions

- Available in sizes up to 24″

- provides lateral restraint of a piping system, allowing the pipe designer to control pipe movement and prevent bowing or buckling of the piping system.

- Various styles and options for steel or copper pipe.

September 14, 2022

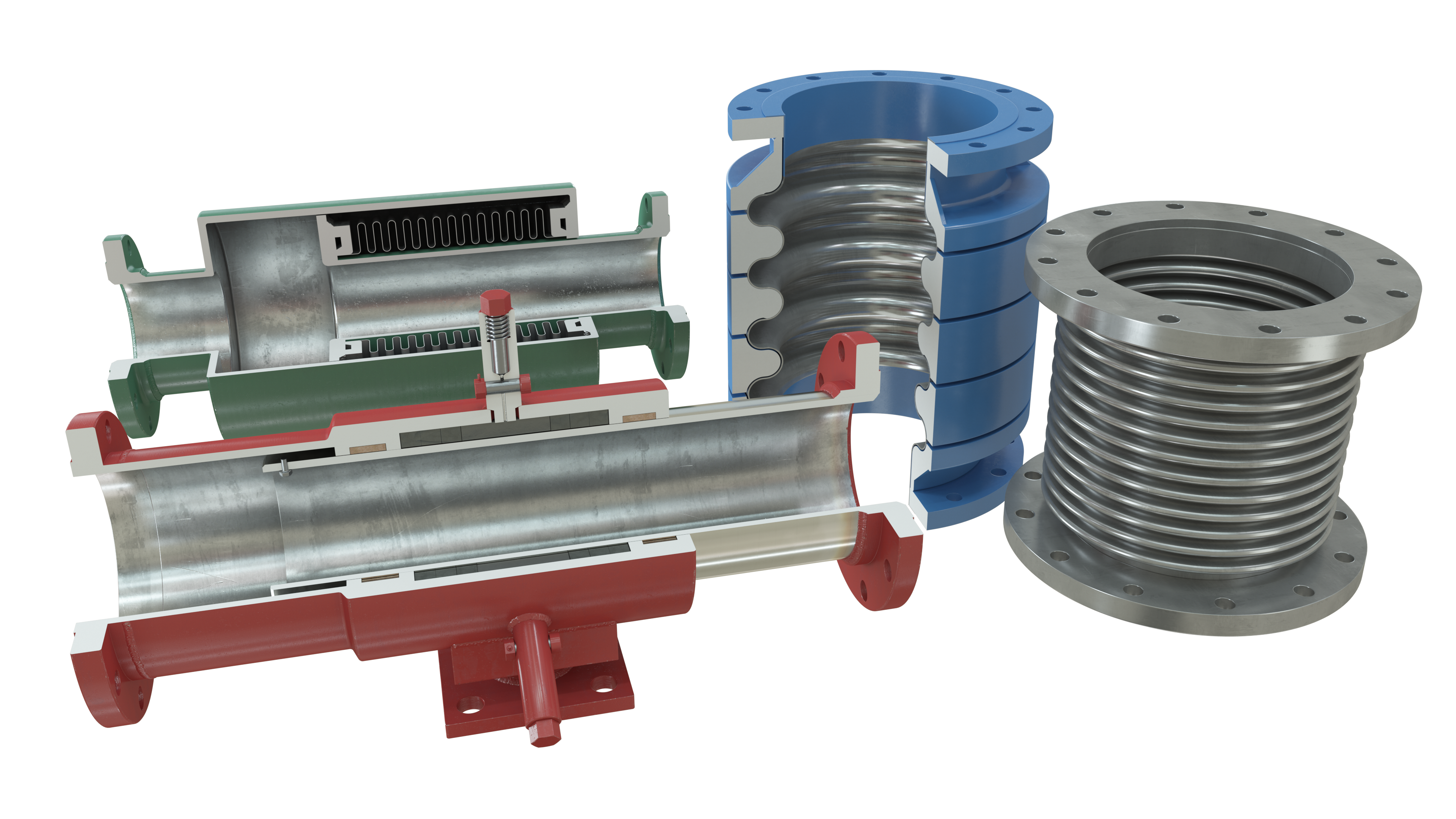

Metragator Metal Expansion Joint The Metragator comes standard for movements of 4″, 6″ and 8″. Available in 150 and 300 psi models and can be configured […]

September 15, 2022

Externally pressurized expansion joints with 3″- 4″ of compensation and .5″ of extension. Allows 2″ – 3″ of compression and .5′ of extension on various options. […]

September 15, 2022

Vane Flex Reduces discharge turbulence in a fraction of space Hydrodynamic shaped vanes Protects valves immediately downstream of pump Equals 5-10 pipe diameter turbulence reduction Less […]

September 15, 2022

Available in sizes up to 24″ provides lateral restraint of a piping system, allowing the pipe designer to control pipe movement and prevent bowing or buckling […]

September 15, 2022

Increase equipment performance, remove debris Designed for straight, smooth flow Maximize pump life from iron oxide build-up 2″ – 16″ at 125 psi Steam options up […]

September 15, 2022

Metraflex Wall Penetration Seals create a mechanical water-tight seal, filling the space around any round pipe including: concrete, steel, plastic, cast iron, copper, and electrical conduit. […]

September 14, 2022

The typical Metraloop installation is axial for thermal applications, or in any possible direction for seismic applications – including axial, lateral and angular. Piping systems are used […]

September 14, 2022

The Metrasphere is most commonly used as a pump or equipment connector. Reduce noise and vibration Reduce pipe stress on your system Handles movement in all […]

September 15, 2022

Higher Operating Pressures: VRF/VRV systems operate at significantly higher pressures than traditional hydronic systems Extreme Test Pressures: Can reach up to 700 psi High Operating Temperatures: […]