Steam

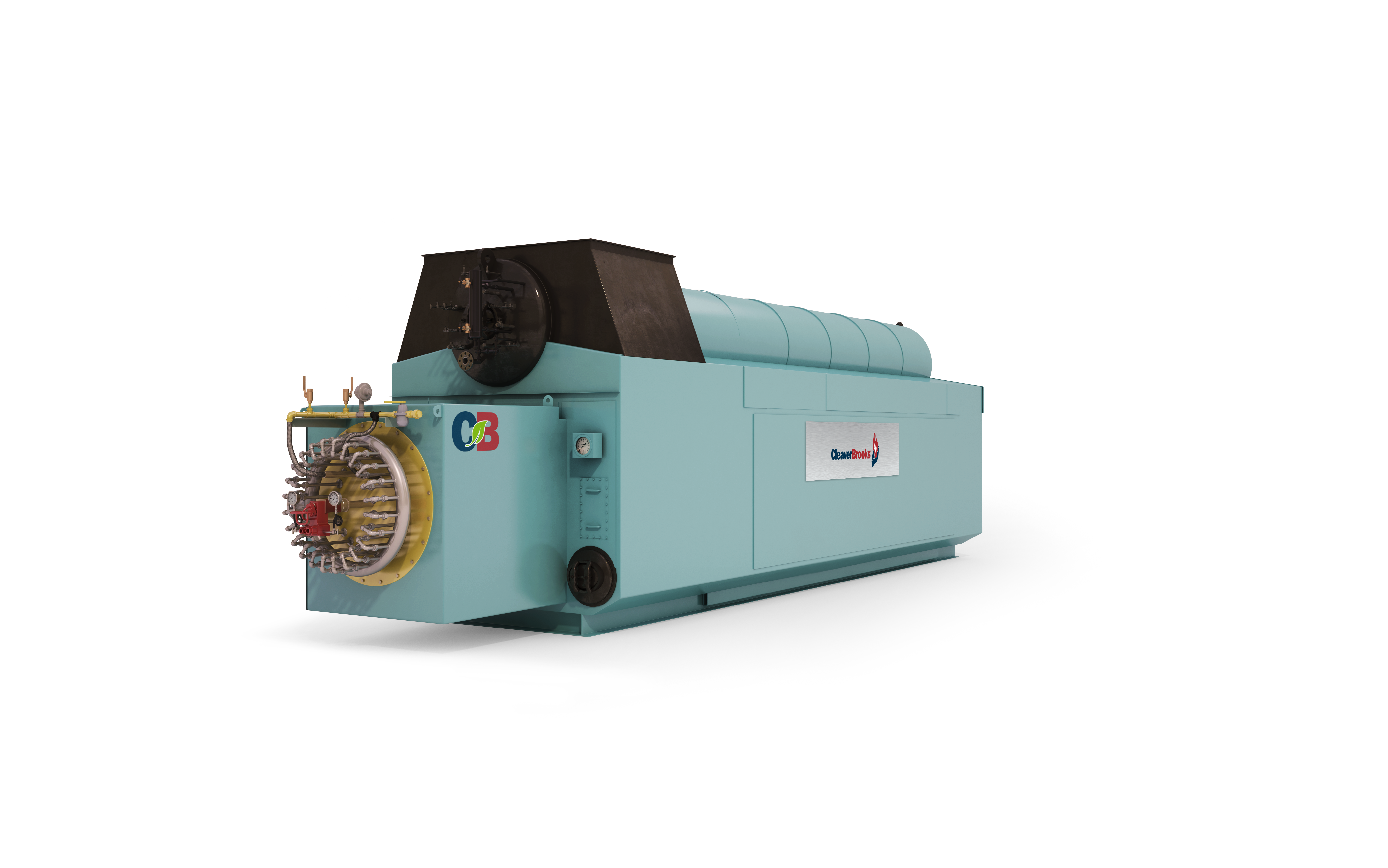

- Vertical Tubeless design for reliability and longevity

- Compact footprint with side-mounted burner

- Large steam space

- Up to 50 HP

- Natural gas, propane

- 15 or 150 psig design

- Up to 84% efficient

- Up to 5:1 turndown

August 13, 2019

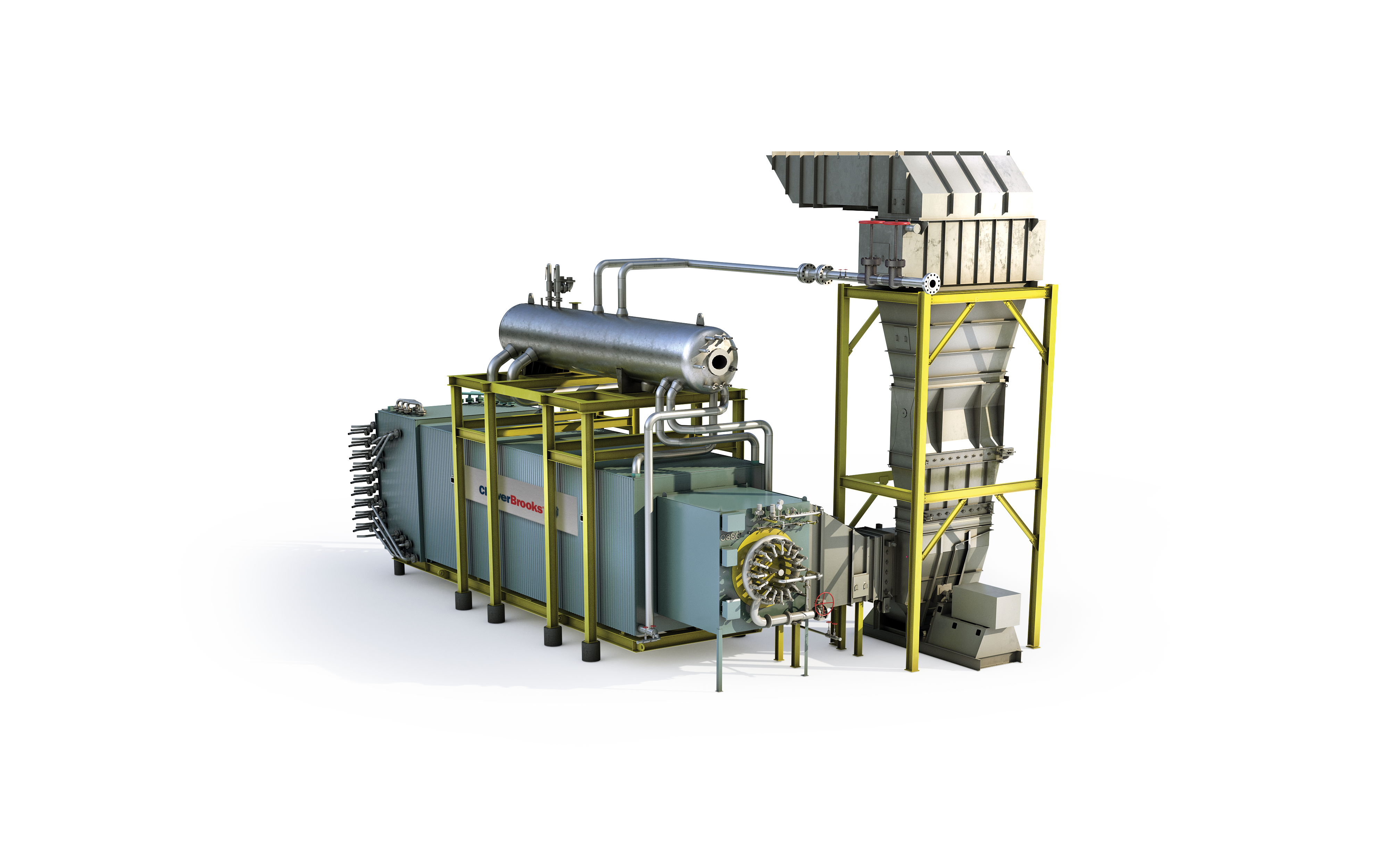

Pre-packaged and pre-engineered Modular design for ease of installation 9.5-240 HP capacities 5-150 psig steam Gas-fired (natural gas or propane Custom-engineered systems available

July 9, 2019

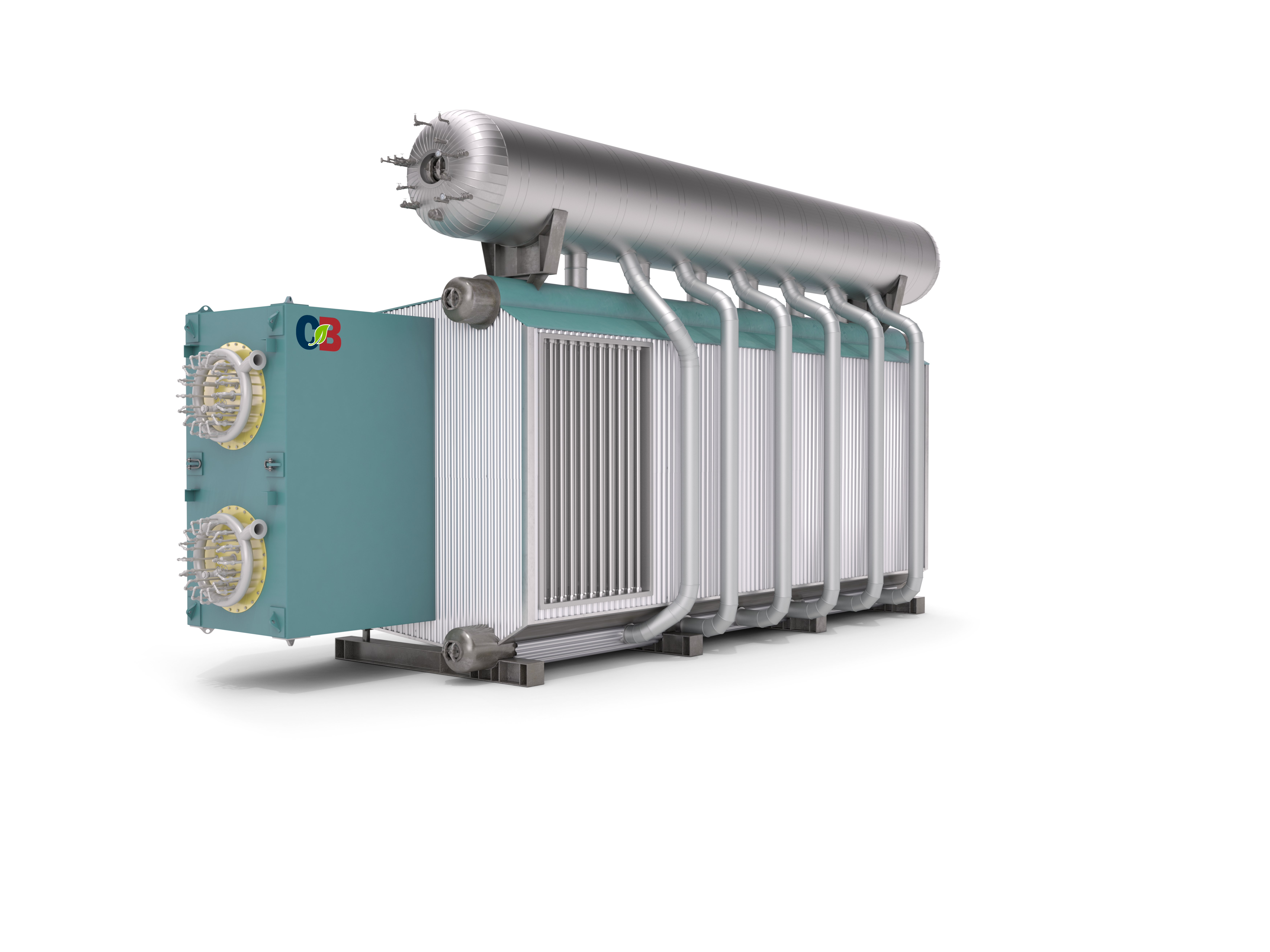

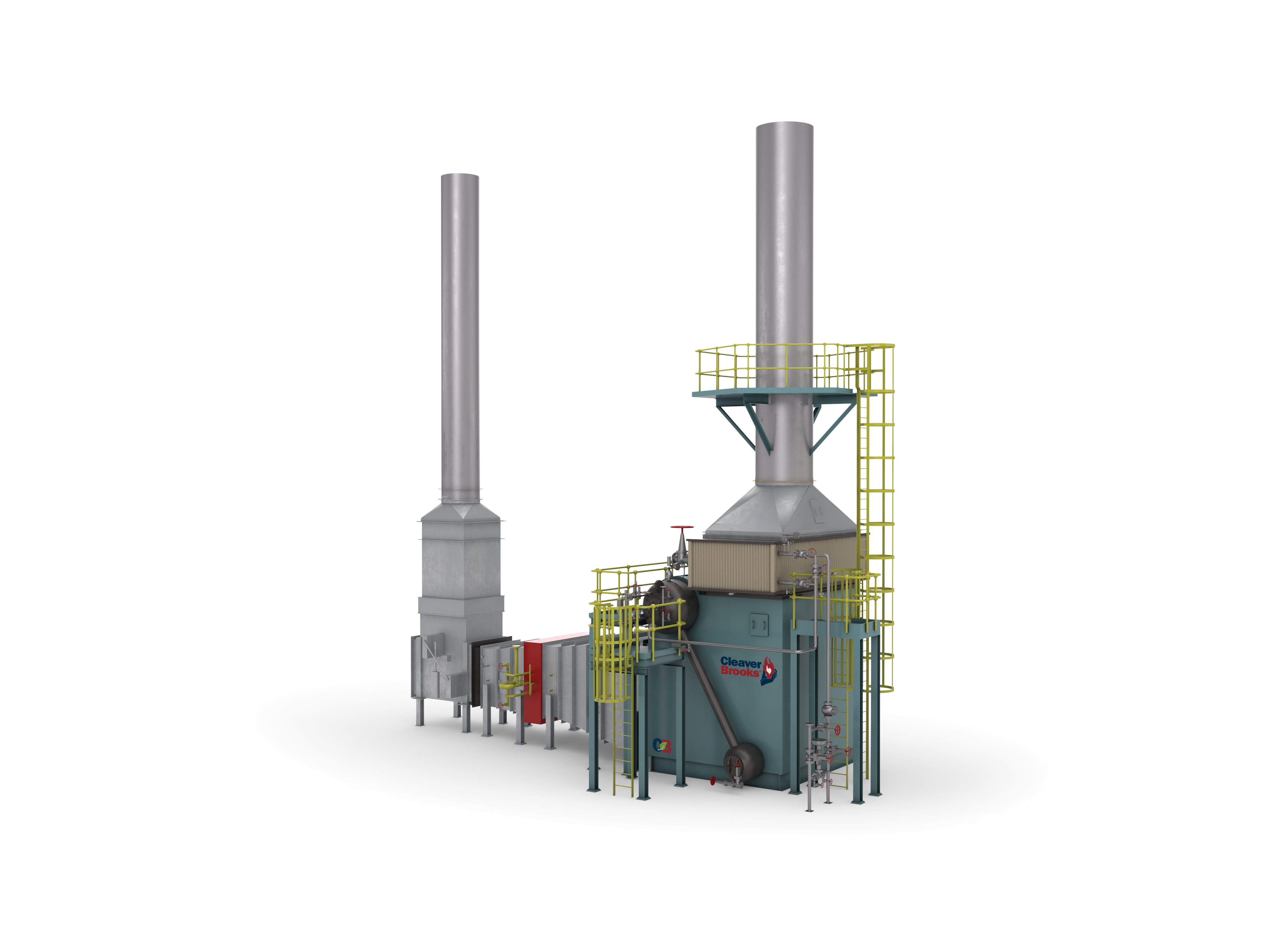

Steam, temperatures to 1,050°F 10,000 to 500,000 lb/hr Natural gas, #2 and #6 oil, alternative fuels, combination Design pressure up to 1,500 psig Available to less […]

July 9, 2019

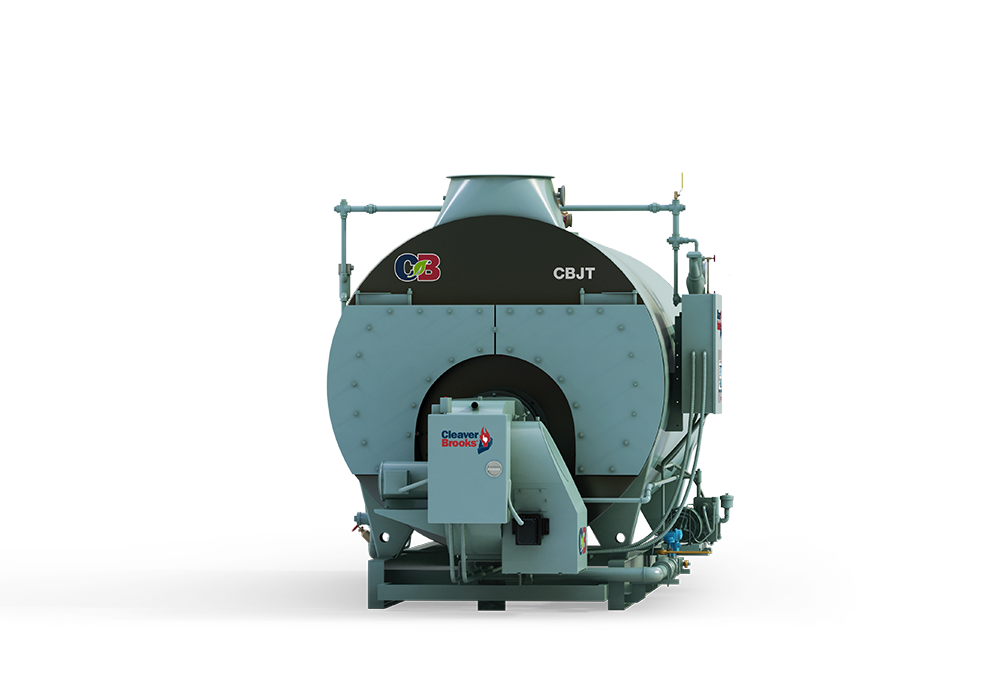

Saturated Steam 100% membrane water-cooled furnace 10,000 to 225,000 lb/hr Natural Gas, Propane Digester, #2 Light Oil 100 to 550 psig on steam Available to less […]

August 9, 2019

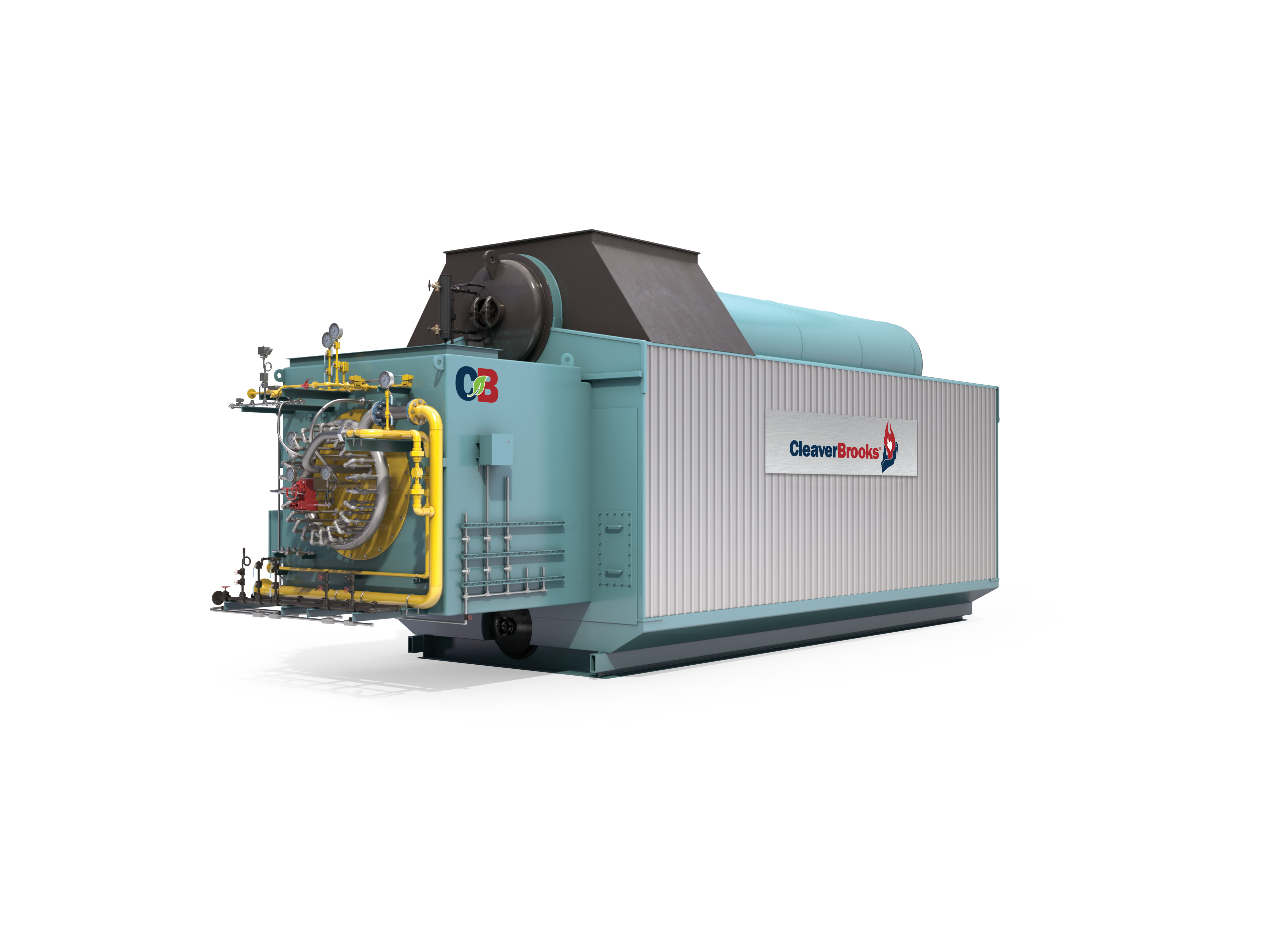

Steam up to 300 psig Hot water up to 125 psig 100 to 2,500 HP 2 Pass and 3 Pass Natural gas/propane, #2 light oil, combination Waterback or […]

August 9, 2019

Steam up to 300 psig Hot water up to 125 psig 50 to 1,600 HP 2, 3 and 4 Pass Natural gas/propane, #2 light oil, #6 oil or […]

August 9, 2019

Steam up to 300 psig Hot water up to 125 psig 50 to 800 HP 4 Pass Natural gas/propane, #2 and #6 oil, combination Alternate fuel capability […]

January 4, 2022

Vertical Tubeless design for reliability and longevity Compact footprint with side-mounted burner Large steam space Up to 50 HP Natural gas, propane 15 or 150 psig […]

January 4, 2022

Low and high-pressure steam boiler 10-125 HP Natural gas, propane or combination 15 or 150 psig design pressure Up to 85% efficient Up to 15:1 fully modulating […]

July 9, 2019

Steam, temperatures to 1,050°F 200,000 to 1,000,000 lb/hr Natural Gas, #2 and #6 oil, refinery fuels, alternative fuels, combination Design pressure up to 1,800 psig Available to […]

July 9, 2019

Steam, temperatures to 1,050°F 10,000 to 500,000 lb/hr Natural Gas, #2 and #6 oil, refinery fuels, alternative fuels, combination Design pressure up to 1,800 psig Available […]

August 9, 2019

1,500-25,000 MBH Input Natural Gas, #2 Light Oil, Propane, Digester Gas 15-250 psig Design Pressure Available to <9 ppm NOx Field Erectable

July 9, 2019

Saturated steam 200,000 to 500,000 lb/hr Natural Gas, #2 – #6 oil, refinery fuels, alternative fuels Design pressure up to 2,300 psig Available to less than […]

August 9, 2019

Steam and hot water 3-pass integrated package 100 to 800 HP Natural gas, #2 and #6 oil, combination 15 to 250+ psig on steam 30 to […]

July 9, 2019

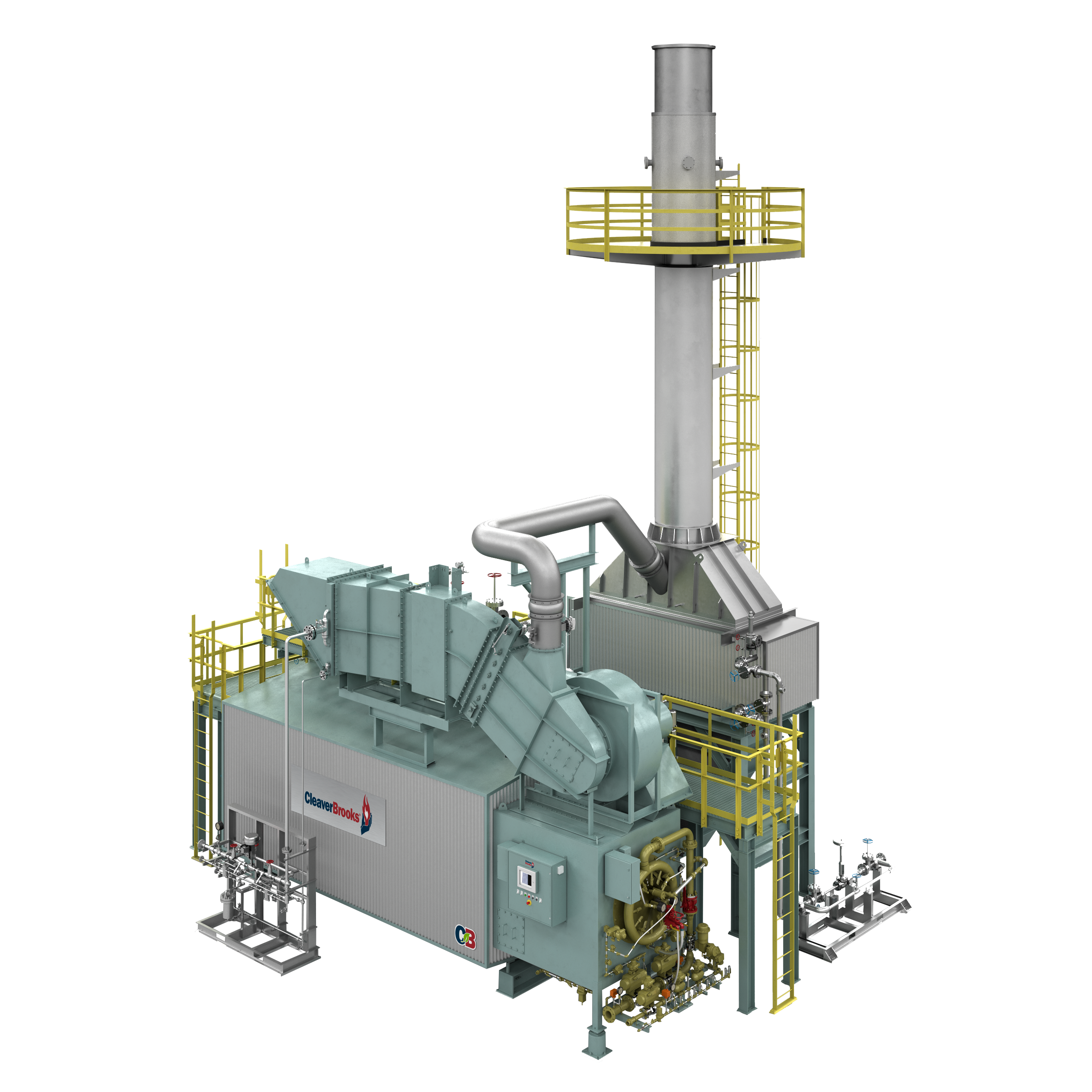

Steam Generation from 10,000 to 500,000 lb/hr Gas flows up to 1,000,000 lb/hr Design pressure up to 1,800 psig Steam temperature to 1,050 °F Supplemental firing with […]

August 12, 2019

Steam or hot water 1.5 to 8.0 MBTU Natural gas, #2 oil, propane 15 to 500 psig (special to 675 psig) on steam 140 psig on […]

August 9, 2019

Electric vertical steam boiler with condensate return tank and pump assembly 12 to 563 KW – up to 1,969 lb/hr Up to 600V 15, 150, 200 […]

August 9, 2019

Electric horizontal steam boiler 1560 to 3375 kW Electrical power 15, 150, 200 & 250 psig No localized emissions

August 9, 2019

Electric vertical steam boiler 12 to 2250 KW – up to 7,875 lb/hr Up to 600V 15, 150, 200 & 250 psig No site emissions

July 9, 2019

Steam, temperatures to 1,050°F 10,000 to 500,000 lb/hr Natural Gas, #2 and #6 oil, refinery fuels, alternative fuels, combination Design pressure up to 1,800 psig Available […]

August 9, 2019

Steam up to 300 psig 100 to 225 HP Natural gas/propane, #2 light oil, combination Waterback or Dryback design

July 9, 2019

Gas Flows to 400,000 lbs/hr Steam generation from 10,000 to 150,000 lb/hr Design pressure up to 1,800 psig Steam temperature to 1,050 °F Supplemental firing with […]

August 9, 2019

Electric Steam Boiler Custom Sizes Available Carbon or Stainless Steel Up to 1,000 kW, 15 to 300 psig

August 12, 2019

Vertical Tubeless 2-Pass, Rugged, Reliable Size Range: 4-60 BHP COMBO gas/oil, COMBO gas/LP 20 ppm LoNOx on Natural Gas 15 to 300 PSIG Maximum Working Pressure […]

August 12, 2019

High-Efficient Vertical Tubeless Steam Boiler Enhanced 2-Pass 6-30 HP, 15 to 300 psig Natural Gas Only 20 ppm Low NOx