Products

Check out our boiler room tips, case studies and resources to maintain your boiler equipment for optimum efficiency, reliability and safety.

August 13, 2019

A steam accumulator is a smart method to reduce severe boiler loading and cycling, when short-duration, high flow steam is required. An accumulator can reduce the […]

August 13, 2019

The vent condenser is a plume abatement device that reduces water/ice or corrosion near the steam vent. Vented steam is directed into the unit and condensed […]

August 13, 2019

No moving parts Easily installed Corrosion-resistant materials Safety protected Extended surface Computerized selection One-year guarantee Quality construction

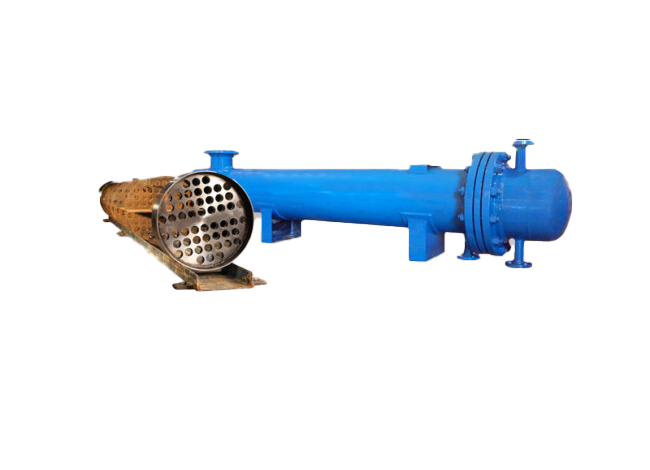

August 13, 2019

Cannon has full capabilities to design, build, rebuild, or repair your heat exchanger. We are experts in our ability to solve customers’ problems through innovative design […]

August 12, 2019

Steam and hot water applications Protects against corrosion Reduces boiler scaling Packaged unit for easy Installation For any size boiler

July 9, 2019

Steam, temperatures to 1,050°F 10,000 to 500,000 lb/hr Natural gas, #2 and #6 oil, alternative fuels, combination Design pressure up to 1,500 psig Available to less […]

August 12, 2019

Prevents buildup of harmful solids Reduces boiler scale Uses lash purification For steam boilers Up to 1,600 psig available

August 12, 2019

Atmospheric pressure Flexible controls options Steam and Hot Water applications Up to 1,000 gallons

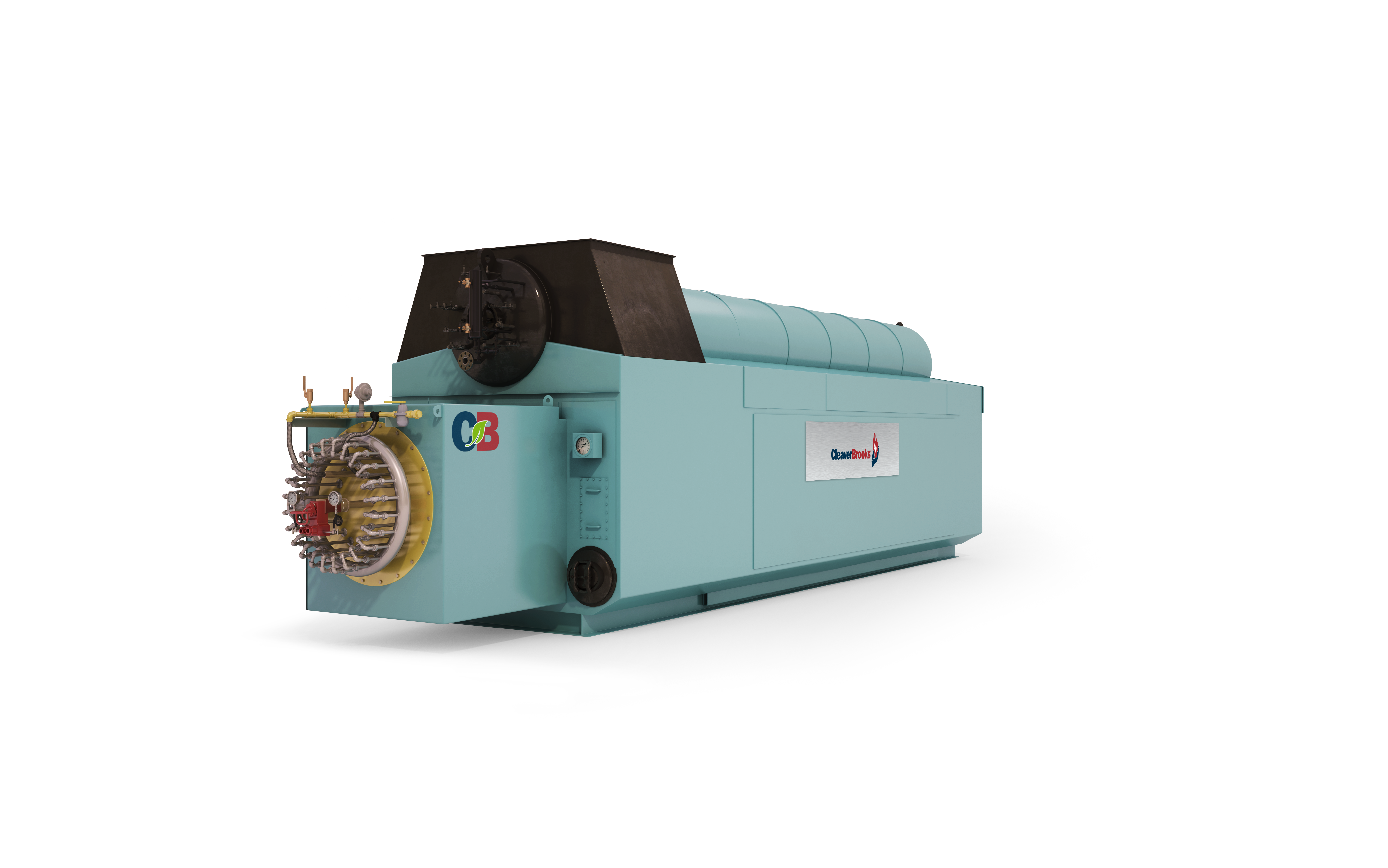

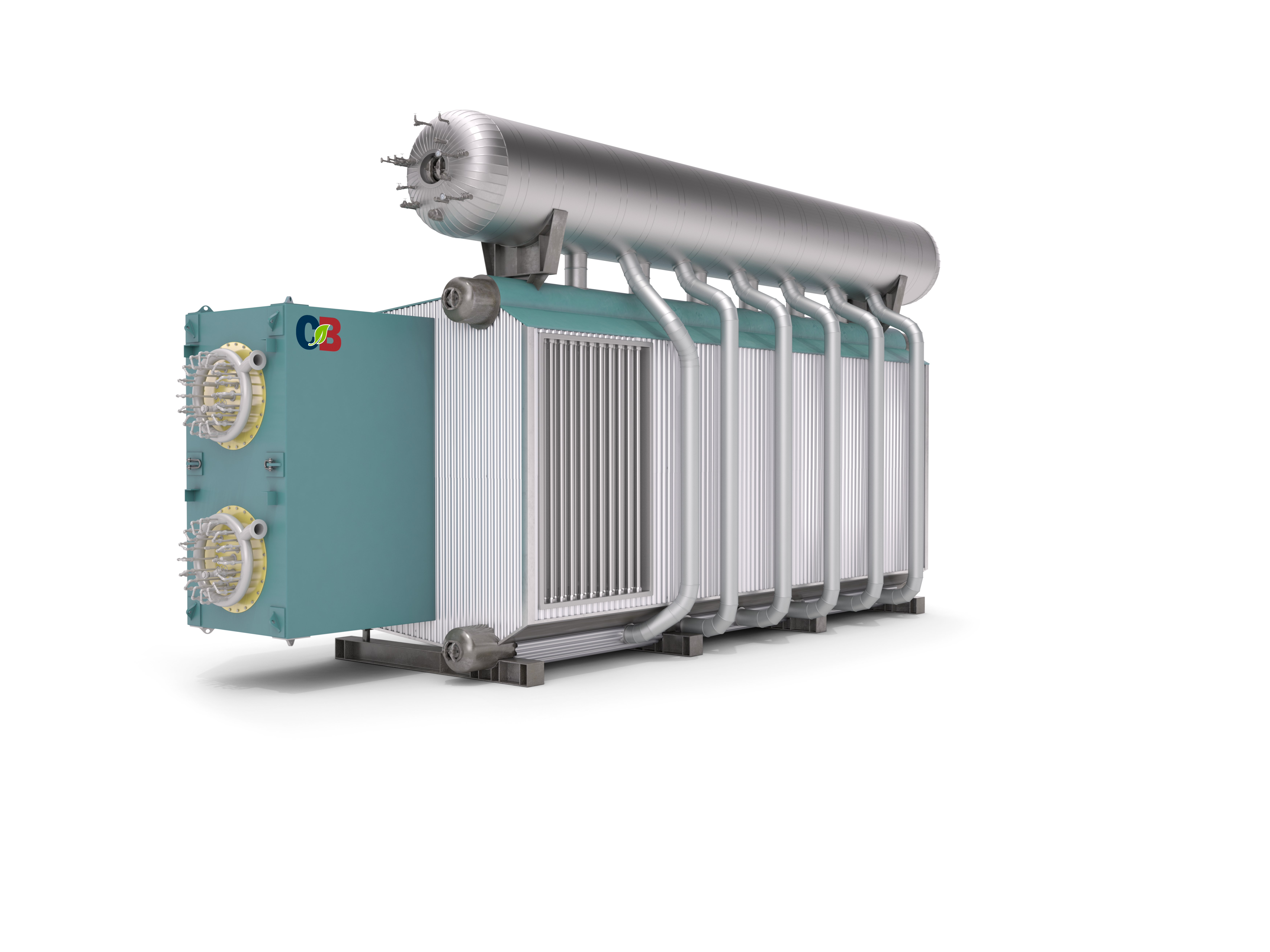

July 9, 2019

Saturated Steam 100% membrane water-cooled furnace 10,000 to 225,000 lb/hr Natural Gas, Propane Digester, #2 Light Oil 100 to 550 psig on steam Available to less […]

August 9, 2019

Steam up to 300 psig Hot water up to 125 psig 100 to 2,500 HP 2 Pass and 3 Pass Natural gas/propane, #2 light oil, combination Waterback or […]

August 9, 2019

Steam up to 300 psig Hot water up to 125 psig 50 to 1,600 HP 2, 3 and 4 Pass Natural gas/propane, #2 light oil, #6 oil or […]

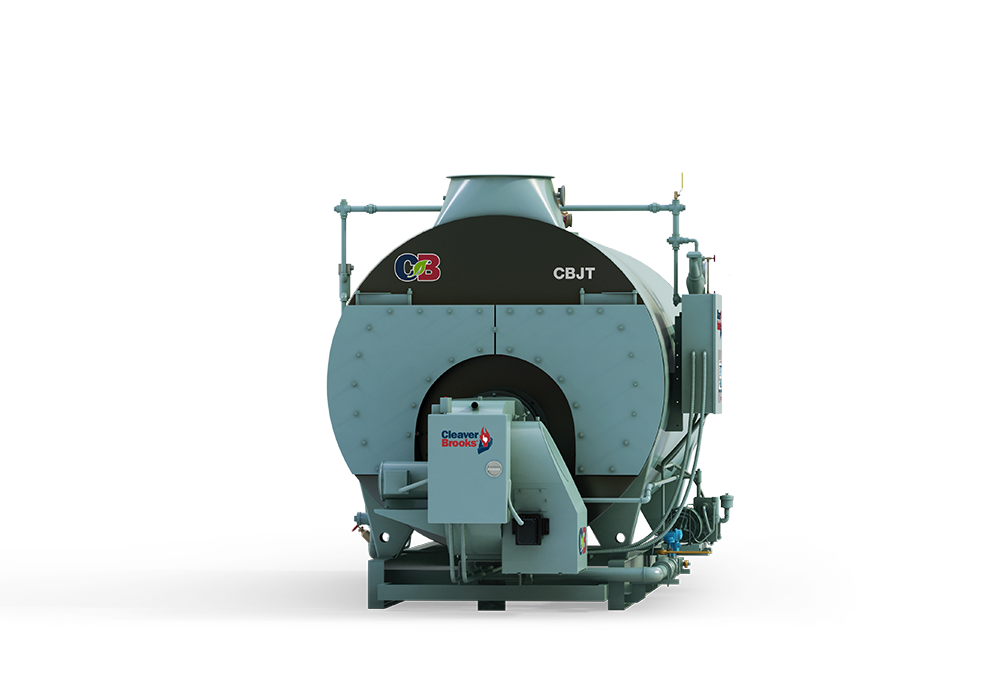

August 9, 2019

Steam up to 300 psig Hot water up to 125 psig 50 to 800 HP 4 Pass Natural gas/propane, #2 and #6 oil, combination Alternate fuel capability […]

January 4, 2022

Vertical Tubeless design for reliability and longevity Compact footprint with side-mounted burner Large steam space Up to 50 HP Natural gas, propane 15 or 150 psig […]

January 4, 2022

Low and high-pressure steam boiler 10-125 HP Natural gas, propane or combination 15 or 150 psig design pressure Up to 85% efficient Up to 15:1 fully modulating […]

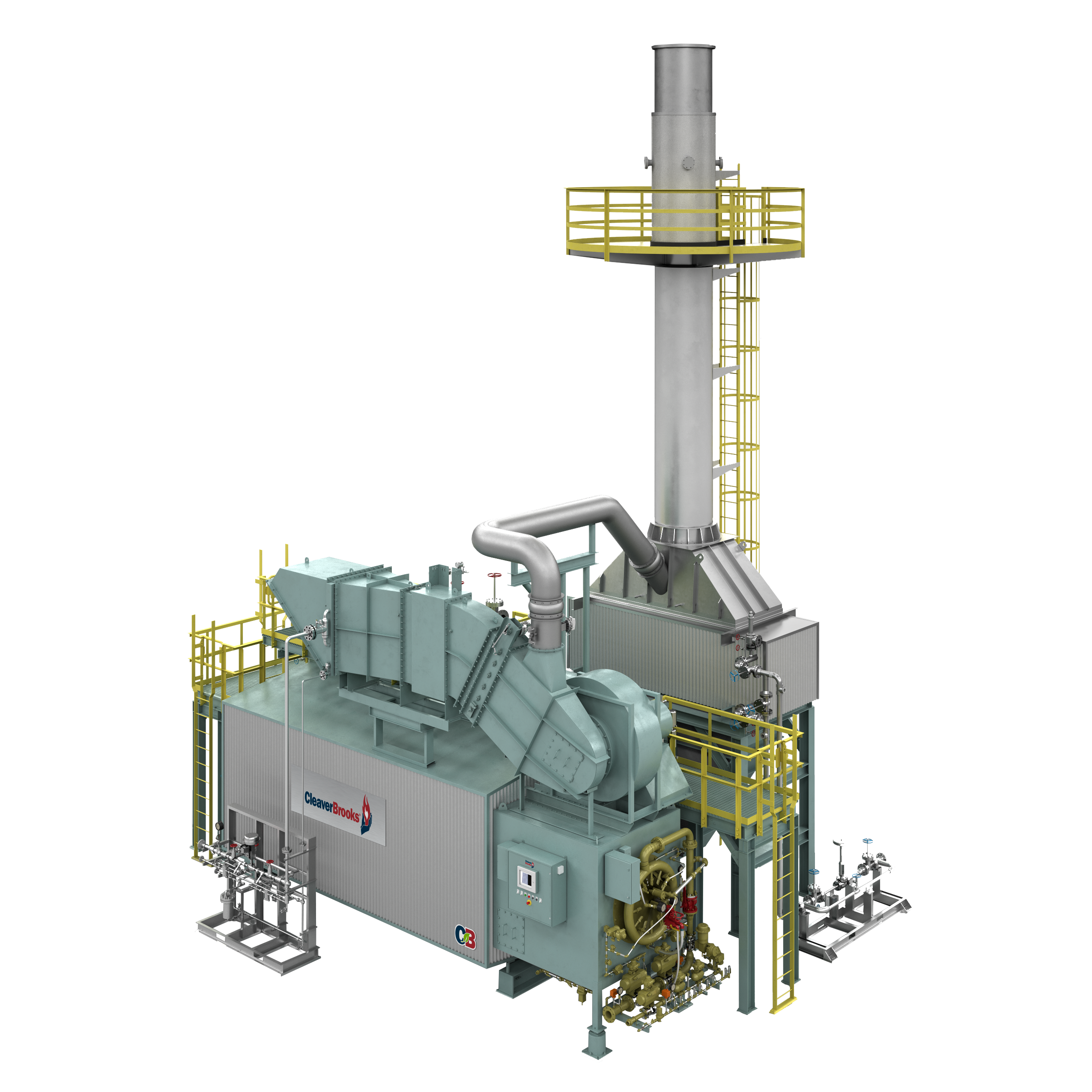

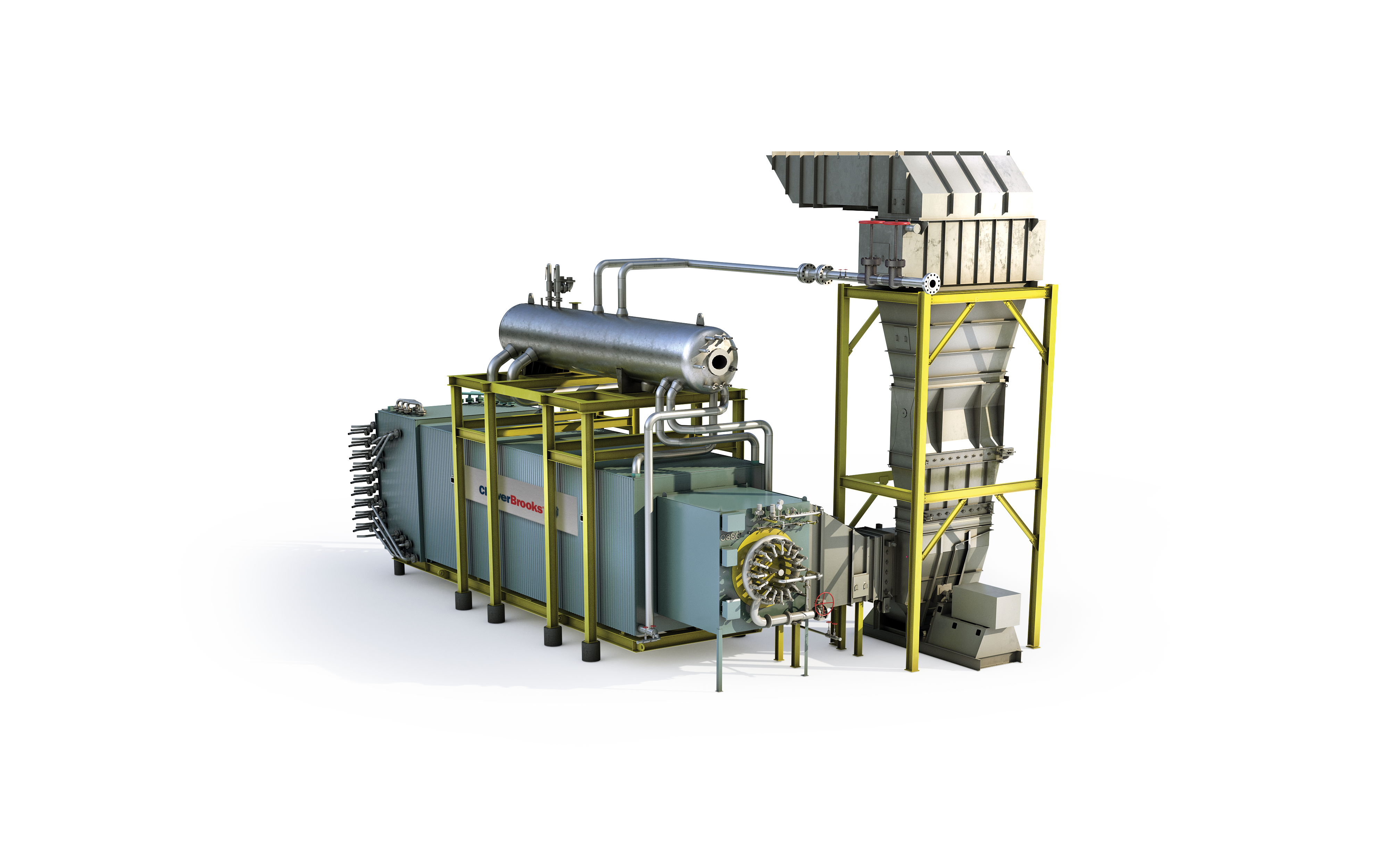

July 9, 2019

Steam, temperatures to 1,050°F 200,000 to 1,000,000 lb/hr Natural Gas, #2 and #6 oil, refinery fuels, alternative fuels, combination Design pressure up to 1,800 psig Available to […]

July 9, 2019

Steam, temperatures to 1,050°F 10,000 to 500,000 lb/hr Natural Gas, #2 and #6 oil, refinery fuels, alternative fuels, combination Design pressure up to 1,800 psig Available […]

August 12, 2019

Steam and Hot Water Applications Sized from 10,000 to 980,000 grains capacity Flow rates from 10 to 300 gpm Tank sizes range from 9″ to 72″ […]

August 12, 2019

Electrical Hydronic Boiler 90 to 540 kW, up to 335 – 1850 MBTu 480 – 600V 160 psig Zero-emissions

August 12, 2019

Electric horizontal steam boiler 1560 to 3375 kW, up to 11,813 lb/hr Electrical power 15, 150, 200 & 250 psig No site emissions

August 9, 2019

1,500-25,000 MBH Input Natural Gas, #2 Light Oil, Propane, Digester Gas 15-250 psig Design Pressure Available to <9 ppm NOx Field Erectable

July 9, 2019

Saturated steam 200,000 to 500,000 lb/hr Natural Gas, #2 – #6 oil, refinery fuels, alternative fuels Design pressure up to 2,300 psig Available to less than […]

August 12, 2019

New or Retrofit applications: Quickly improve burner performance and achieve maximum efficiency. User-friendly setup and operation. Complete boiler control system Proven Allen Bradley PLC platform Advanced […]

August 9, 2019

Steam and hot water 3-pass integrated package 100 to 800 HP Natural gas, #2 and #6 oil, combination 15 to 250+ psig on steam 30 to […]

August 12, 2019

Designed and optimized to make your boiler room more efficient and save you money.