Products

Check out our boiler room tips, case studies and resources to maintain your boiler equipment for optimum efficiency, reliability and safety.

July 9, 2019

Steam Generation from 10,000 to 500,000 lb/hr Gas flows up to 1,000,000 lb/hr Design pressure up to 1,800 psig Steam temperature to 1,050 °F Supplemental firing with […]

August 12, 2019

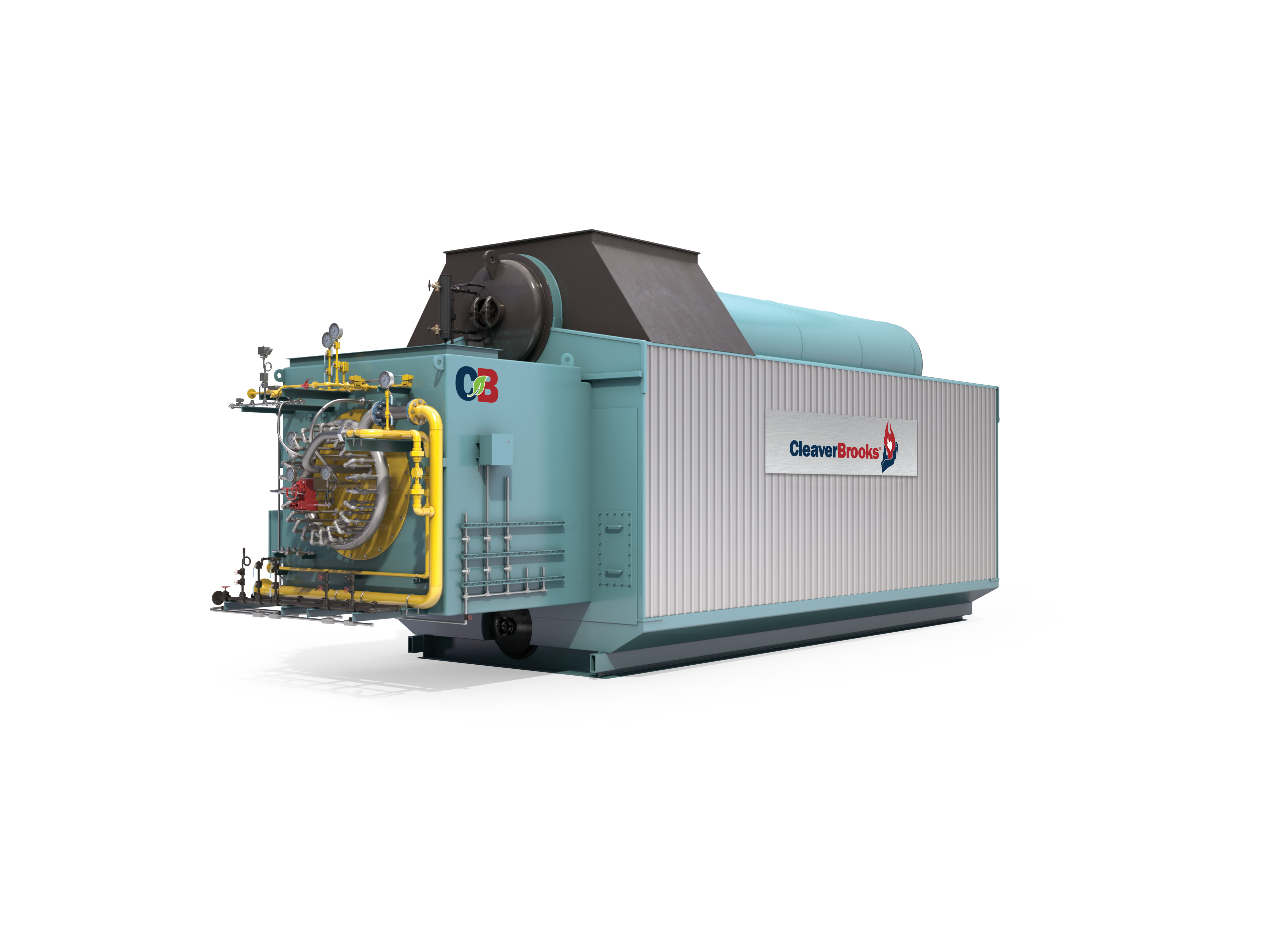

Steam or hot water 1.5 to 8.0 MBTU Natural gas, #2 oil, propane 15 to 500 psig (special to 675 psig) on steam 140 psig on […]

August 9, 2019

Electric vertical steam boiler with condensate return tank and pump assembly 12 to 563 KW – up to 1,969 lb/hr Up to 600V 15, 150, 200 […]

August 9, 2019

Electric horizontal steam boiler 1560 to 3375 kW Electrical power 15, 150, 200 & 250 psig No localized emissions

August 9, 2019

Electric vertical steam boiler 12 to 2250 KW – up to 7,875 lb/hr Up to 600V 15, 150, 200 & 250 psig No site emissions

August 12, 2019

Electric hot water boiler 12 to 3360 kW, up to 11.5 million Btu/hr Up to 600V 160, 200 & 250 psig No site emissions

July 9, 2019

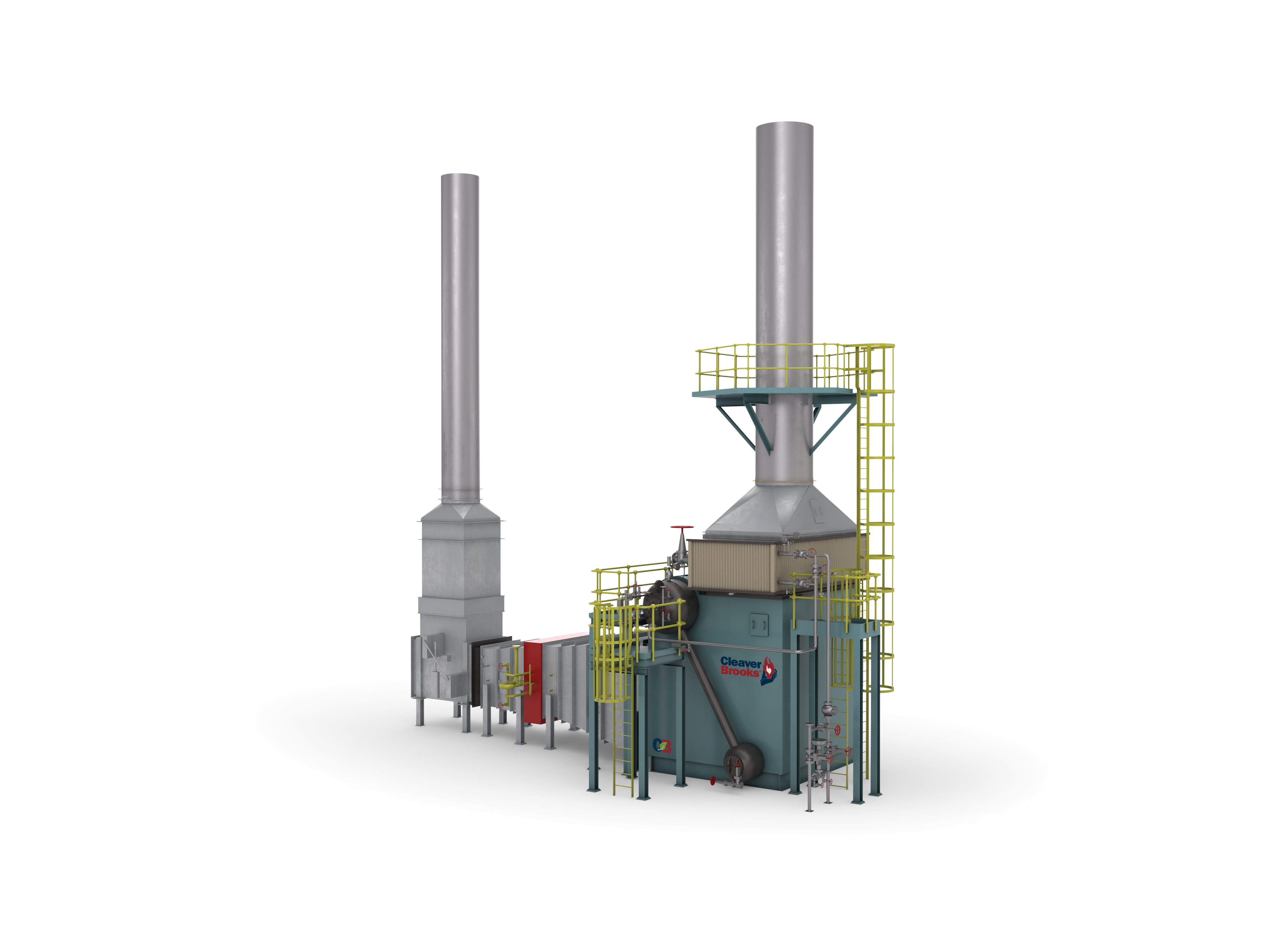

Steam, temperatures to 1,050°F 10,000 to 500,000 lb/hr Natural Gas, #2 and #6 oil, refinery fuels, alternative fuels, combination Design pressure up to 1,800 psig Available […]

August 9, 2019

Steam up to 300 psig 100 to 225 HP Natural gas/propane, #2 light oil, combination Waterback or Dryback design

August 13, 2019

Supervisory Control And Data Acquisition System – Designed to provide remote operation, graphic display of information, alarm message display, report generation, historical trending, and remote controller […]

July 9, 2019

Gas Flows to 400,000 lbs/hr Steam generation from 10,000 to 150,000 lb/hr Design pressure up to 1,800 psig Steam temperature to 1,050 °F Supplemental firing with […]

August 12, 2019

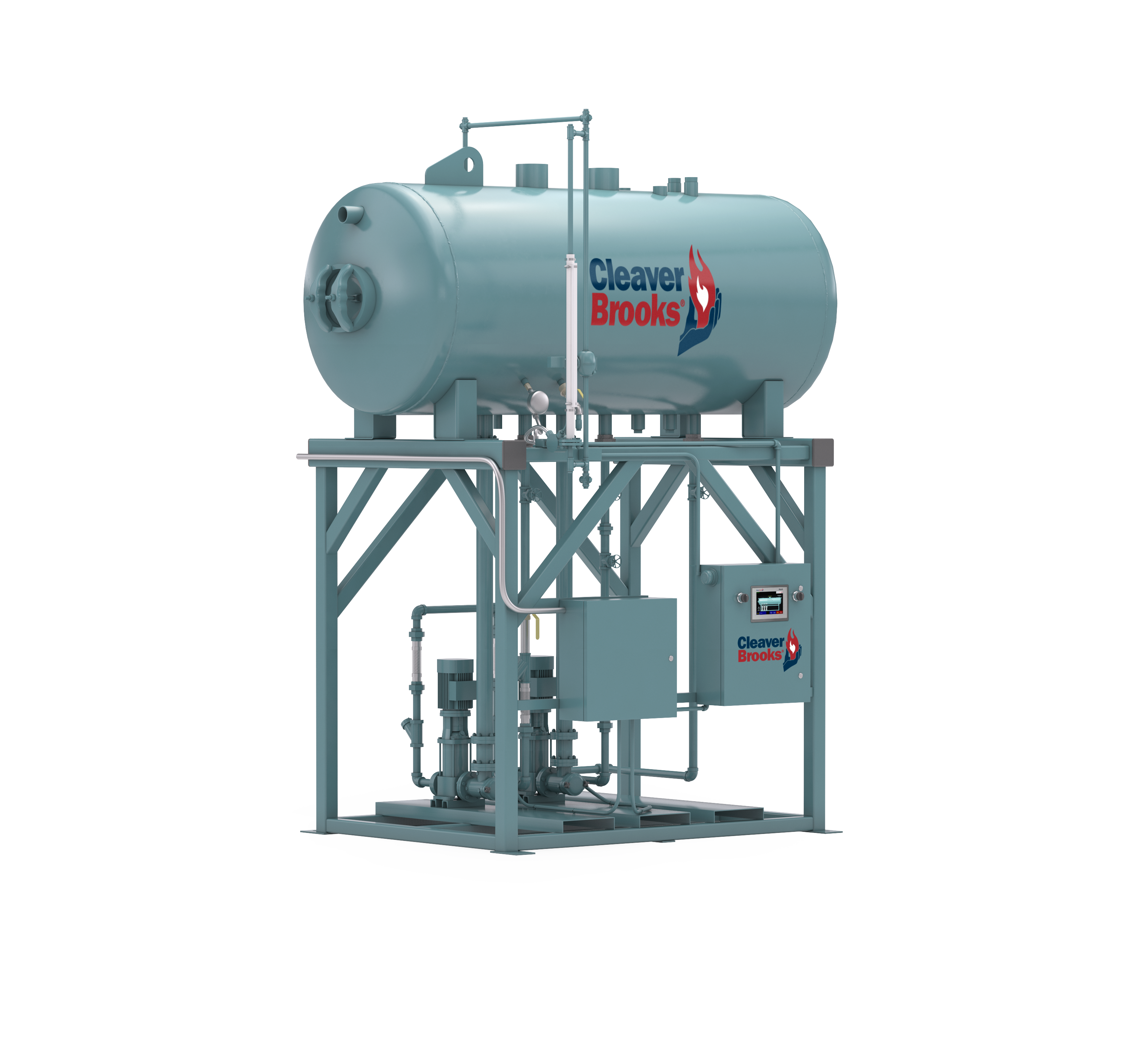

Condensate surge tank 300-3,600 gallon capacity On/off or variable speed pumping Steam and Hot Water applications

August 12, 2019

Steam and hot water applications Removes oxygen from feedwater Vertical or horizontal tray column design Model TMV: 30,000-500,000 lb/hr Model TMH: 500,000-1,000,000 lb/hr On/off and variable […]

August 12, 2019

Steam and hot water applications Sized from 20,000 to 1,500,000 grains exchange capacity Flow rates from 2 to 450 gpm Tanks of FRP plastic or steel […]

August 12, 2019

High-quality design and construction Complete package with only four piping connections High-capacity output ANTICIPATOR® temperature control regulates hot water outlet temperatures ±4F Copper-nickel shell, naval brass […]

August 12, 2019

Steam applications Two-stage condensing economizer Ideal for larger boilers Boilers up to 2,500 HP Accommodates all boiler design pressures

August 12, 2019

Custom-designed combustion control and burner management control units to meet the needs of your specific boiler system.

August 19, 2019

typical configuration is a double wall tank with a closed interstitial space for leak monitoring. A second configuration is an open top rupture basin where the […]

February 26, 2025

High-temperature flowmeter for process applications with a compact, easily accessible transmitter

December 28, 2021

The Automatic Damper is an energy-saving device that closes the appliance connector, when the appliance is shut off.

December 28, 2021

Fixed Position Damper used to balance draft in a boiler connector.

December 28, 2021

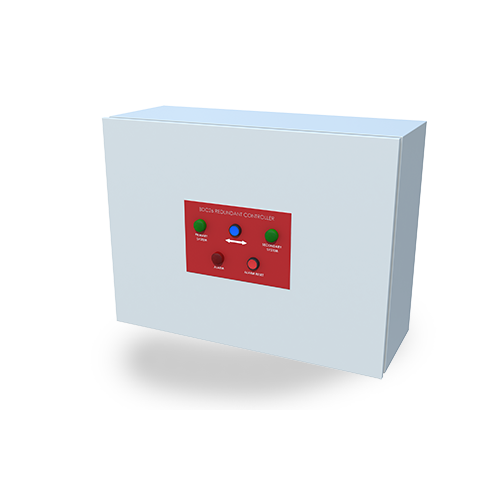

The Redundancy Controller is used when an option to operate a redundant mechanical draft system is required. It allows the safeties to be bypassed in case […]

December 28, 2021

A simple fan and damper control for gas- and oil-fired boilers and water heaters that maintains a set fan speed where modulation is not required.

December 28, 2021

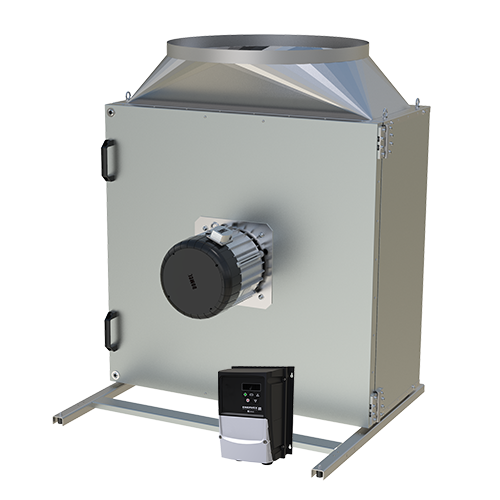

Multi-use, high performing, variable-volume centrifugal exhaust box fan designed for indoor and outdoor installation. Can be used for special exhaust or exhaust of lint-laden air or […]