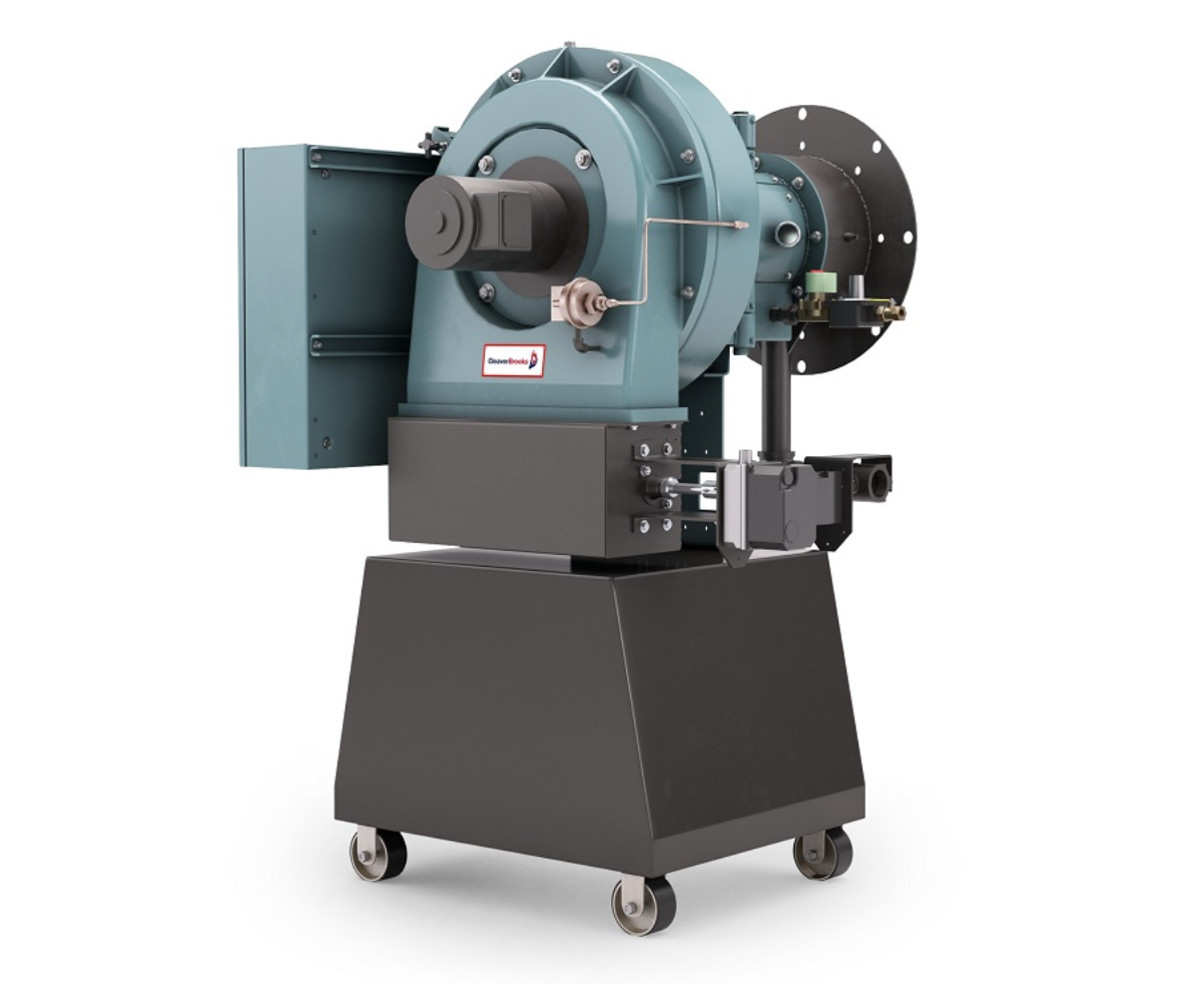

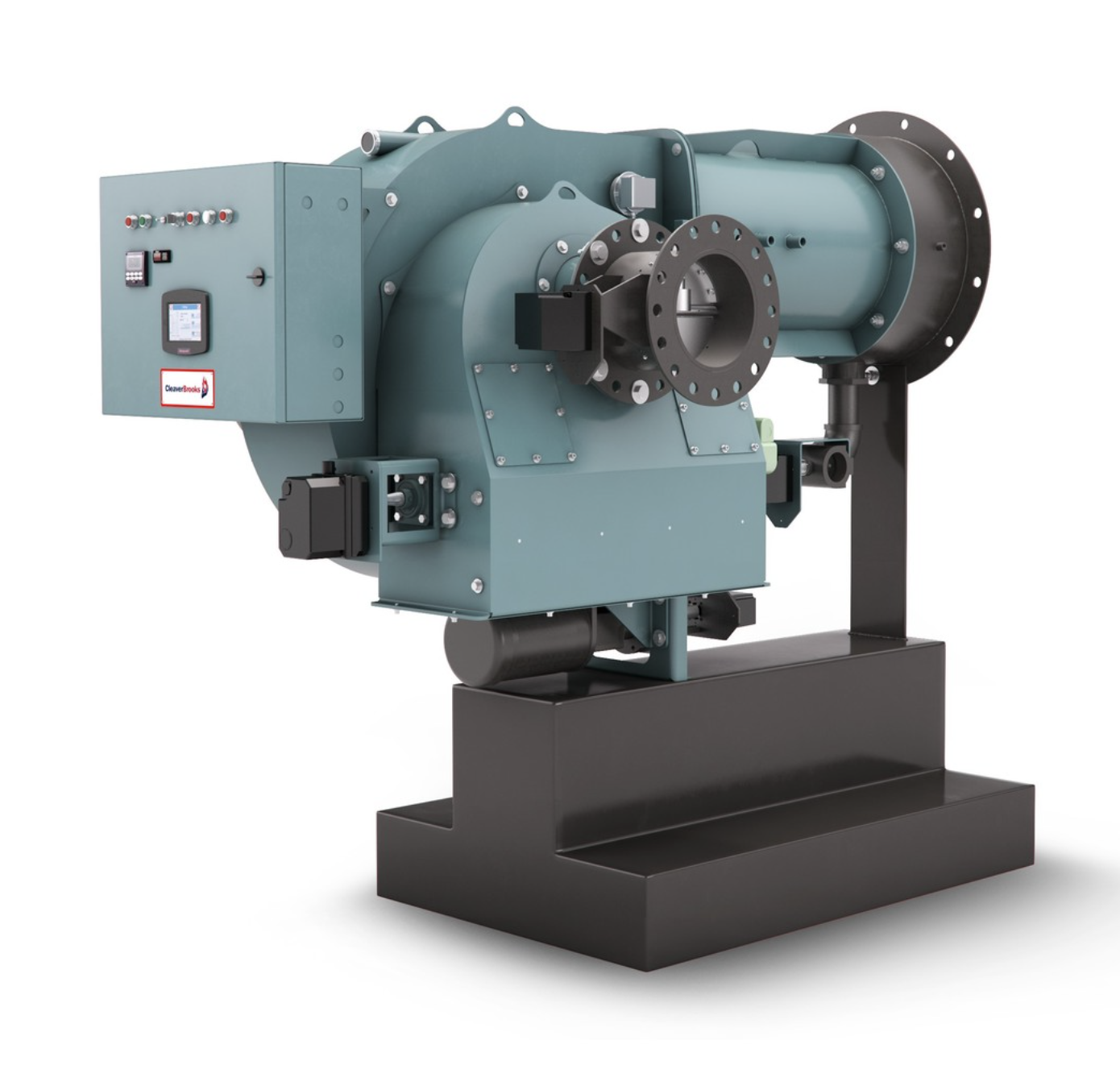

Cleaver Brooks

Cleaver-Brooks is a complete boiler room solutions provider that helps businesses run better every day. It develops hot water and steam generation products aimed at integrating and optimizing the total boiler/burner/controls system to maximize energy efficiency and reliability while minimizing emissions.