Hydronic Solutions

March 19, 2025

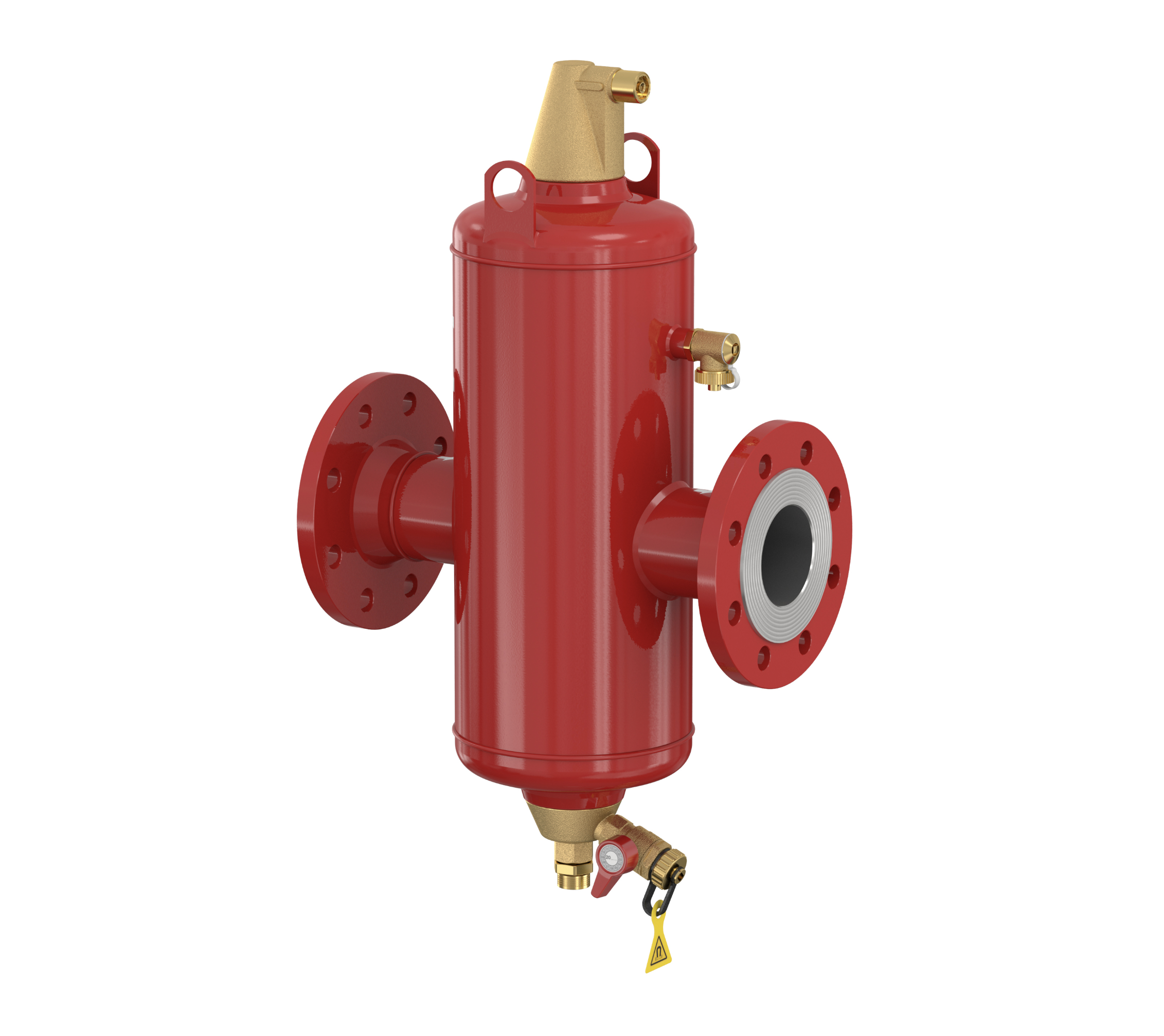

The Commercial Flamcovent Clean Smart air and dirt separator from Flamco removes the smallest microbubble and minuscule dirt particle from the system water. The innovative design […]

March 19, 2025

Compact, proven design for reliability and efficiency in air removal Protective cap with expansion sealer rings to prevent leaks Substantial distance between water and closing mechanism […]

March 21, 2025

Applications Residential heating and cooling; potable water supply Description The Armstrong Compass H is an energy-efficient variable speed wet-rotor circulator. Designed to replace existing fixed speed circulators, with […]

August 9, 2019

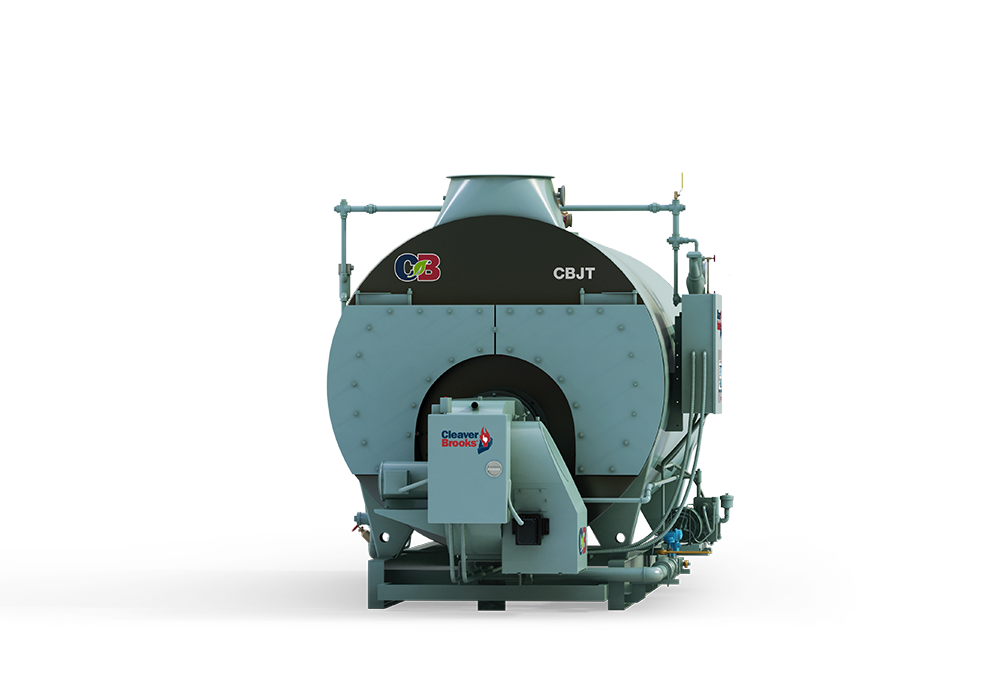

Full condensing hydronic boiler high-mass firetube boiler Compact footprint 500 to 6,000 MBTU Standard less than 20 ppm NOx Up to 99% efficiency Standard dual-return connections […]

August 9, 2019

Size range: 6,000, 10,000, 12,000 MBH capacities Uses: For healthcare facilities, building heat, manufacturing processes, colleges/universities Fuels: Dual fuel condensing – gas with #2 oil back-up or gas-only […]

August 9, 2019

Steam up to 300 psig Hot water up to 125 psig 100 to 2,500 HP 2 Pass and 3 Pass Natural gas/propane, #2 light oil, combination Waterback or […]

August 9, 2019

Steam up to 300 psig Hot water up to 125 psig 50 to 1,600 HP 2, 3 and 4 Pass Natural gas/propane, #2 light oil, #6 oil or […]

August 9, 2019

Steam up to 300 psig Hot water up to 125 psig 50 to 800 HP 4 Pass Natural gas/propane, #2 and #6 oil, combination Alternate fuel capability […]

August 12, 2019

Electrical Hydronic Boiler 90 to 540 kW, up to 335 – 1850 MBTu 480 – 600V 160 psig Zero-emissions

August 12, 2019

Electric horizontal steam boiler 1560 to 3375 kW, up to 11,813 lb/hr Electrical power 15, 150, 200 & 250 psig No site emissions

August 9, 2019

1,500-25,000 MBH Input Natural Gas, #2 Light Oil, Propane, Digester Gas 15-250 psig Design Pressure Available to <9 ppm NOx Field Erectable

August 9, 2019

Steam and hot water 3-pass integrated package 100 to 800 HP Natural gas, #2 and #6 oil, combination 15 to 250+ psig on steam 30 to […]

August 12, 2019

Steam or hot water 1.5 to 8.0 MBTU Natural gas, #2 oil, propane 15 to 500 psig (special to 675 psig) on steam 140 psig on […]

August 12, 2019

Electric hot water boiler 12 to 3360 kW, up to 11.5 million Btu/hr Up to 600V 160, 200 & 250 psig No site emissions

March 19, 2025

Ranging from 4.75 Gallons to 3,963 Gallons Sensor port for pressure gauge Built-in bladder integrity monitor Easily accessible air valve Secure guard mount Replaceable heavy-duty butyl […]

March 20, 2025

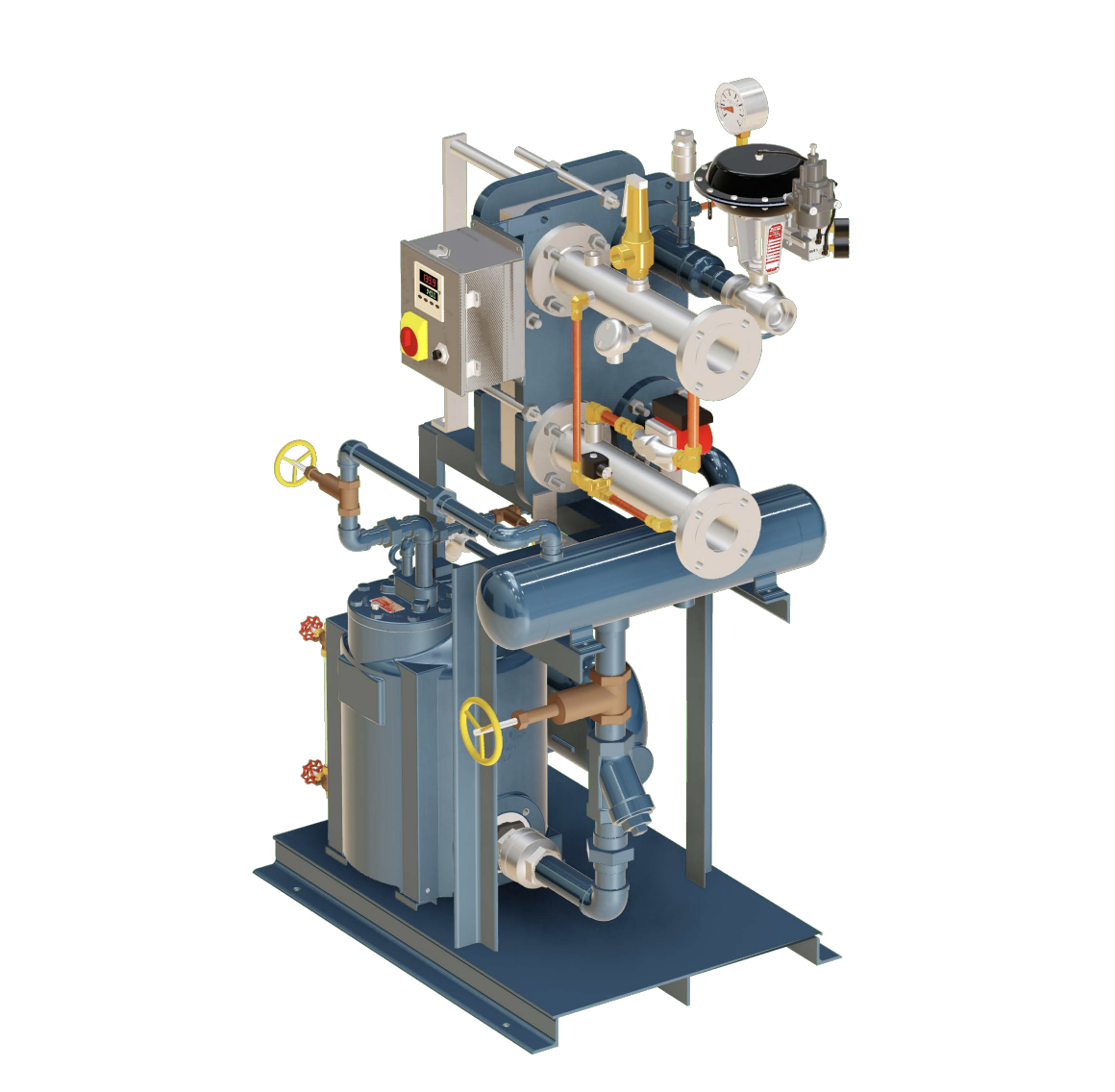

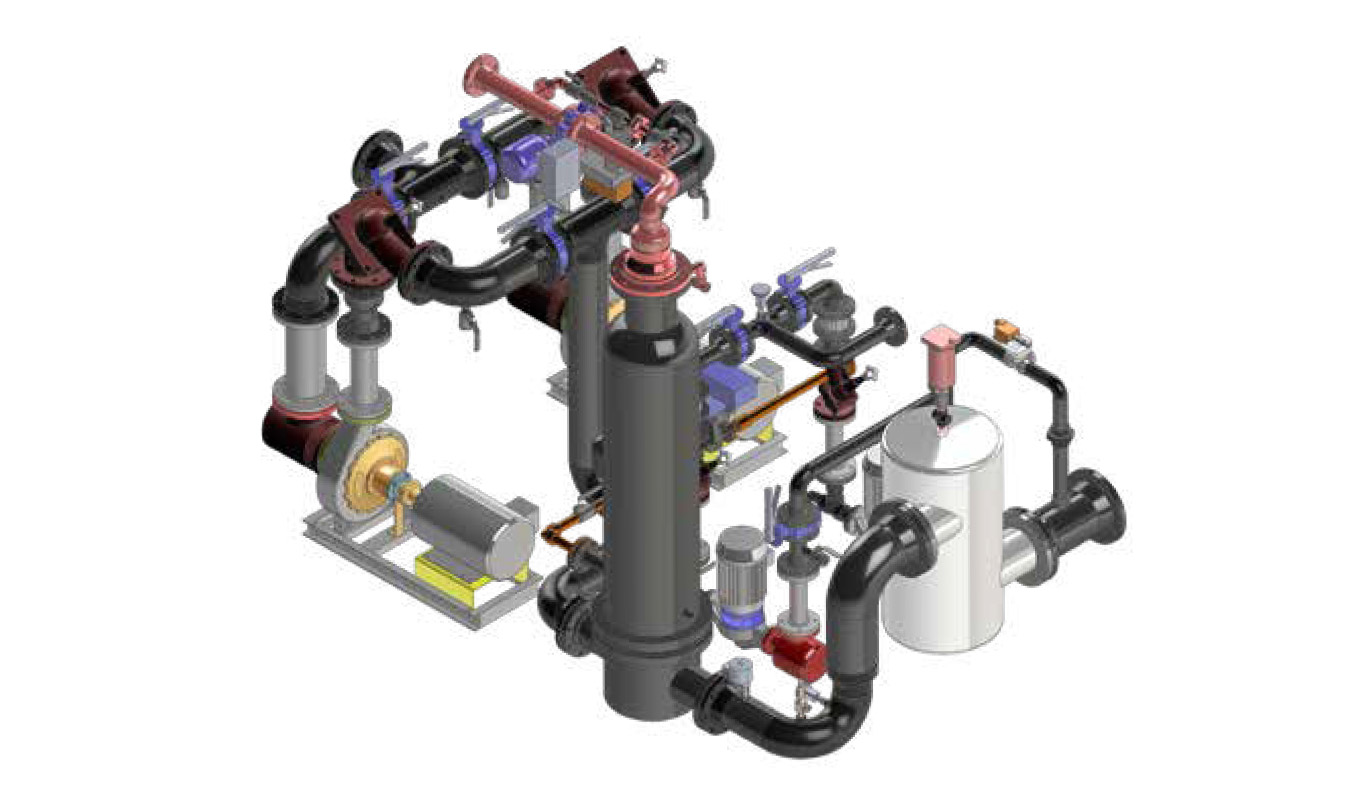

3 package sizes up to 5,152 lbs/hr steam load and up to 100 GPM Compact and energy-efficient water heating solution Fully assembled steam-to-water heater which produces […]

March 19, 2025

Oilon ChillHeat RE 210 – RE 420 Cost-effective solution for cooling and heating Compact design for space efficiency Multiple units can be connected in series for […]

March 19, 2025

Oilon ChiolHeat S 180 – S 580 Compact, high-capacity design for efficient water chilling and heating Equipped with energy-efficient rotary screw compressors and plate heat exchangers […]

March 19, 2025

Oilon ChillHeat S 600 – S 2000 Designed for high heating and cooling capacity applications Equipped with two efficient and reliable screw compressors Features shell and […]

March 19, 2025

Oilon ChillHeat P 30 – P 450 Energy-efficient solution for cooling and heating buildings and industrial processes Utilizes waste heat for heating purposes Equipped with piston […]

September 11, 2019

MCU Steam Heat Exchanger: Modulating condensate with a U-tube design Ultimate Package (UP): Includes circulating pumps and accessories Efficient Steam Control: Control valve installed on the […]

January 5, 2022

Maxi-Therm offers a wide range of different steam water heaters based on your requirements, design and application. To save cost and energy the MCU model is a […]

September 7, 2023

Energy-efficient industrial heat pumps are a tangible solution for reducing emissions. Besides traditional HFC refrigerants, we offer HFO refrigerants with an extremely low or near-zero global […]

August 12, 2019

Size Range: 300-4000 MBTU Equipped with the latest touch-screen technology, the NURO™ Touch-Screen Control All-purpose boiler suitable for condensing and non-condensing systems Revolutionary new, fully independent […]