The Importance of Routine Boiler Tuning

March 24, 2022

Optimize your Boiler System with Upgrades

June 8, 2022Working towards a more sustainable environment is a key focus for most companies today. Reducing carbon dioxide emissions and minimizing the usage of fossil fuels are crucial steps in lessening your carbon footprint. Electric boilers are 100% local emission-free, ideal for meeting decarbonization goals. They are compact, quiet, and provide nearly 100% efficiency at all operating points.

Electric Boilers

Electric boilers have many advantages, including no requirements for flue gas venting, no fuel storage, limited piping, low emissions, economical installation, quiet operation, and minimal maintenance.

Although electric boilers may use electricity generated from fossil fuel-fired generators, a percentage of the electricity can come from carbon-free sources such as wind, solar, nuclear, and waste heat generation. This reduces your carbon footprint, contributing positively to environmental goals. Electric boilers are nearly 100% efficient once electric power is provided and used to generate steam and hot water.

Types and Specifications of Electric Boilers

Commercial and industrial-sized electric boilers come in two types: Immersion Element (also known as Resistance type) and Electrode. These span a range of sizes from approximately 10 kW to over 100 MW, with the Immersion type ranging from roughly 10 to 3400 kW, and the Electrode type covering the larger capacities starting at about 1 MW and spanning to over 100 MW.

For perspective, a kilowatt (kW) equals 1,000 watts, and a megawatt (MW) equals 1,000,000 watts. Additionally, a watt equals 3.412 Btu/Hr. Therefore, one kW equals 3,412 Btu/Hr, and there are 33,472 Btu/Hr in one boiler horsepower. A boiler horsepower also equals 34.5 pounds of steam from and at 212°F feed water temperature. These boilers can be built as hot water heating boilers or for low or high-pressure steam applications.

Most manufacturers build them to arrive at the site as complete packages ready for appropriate connections, including all the controls, insulation, and casing affixed to the skid-mounted pressure vessel.

Emissions-Free Solutions

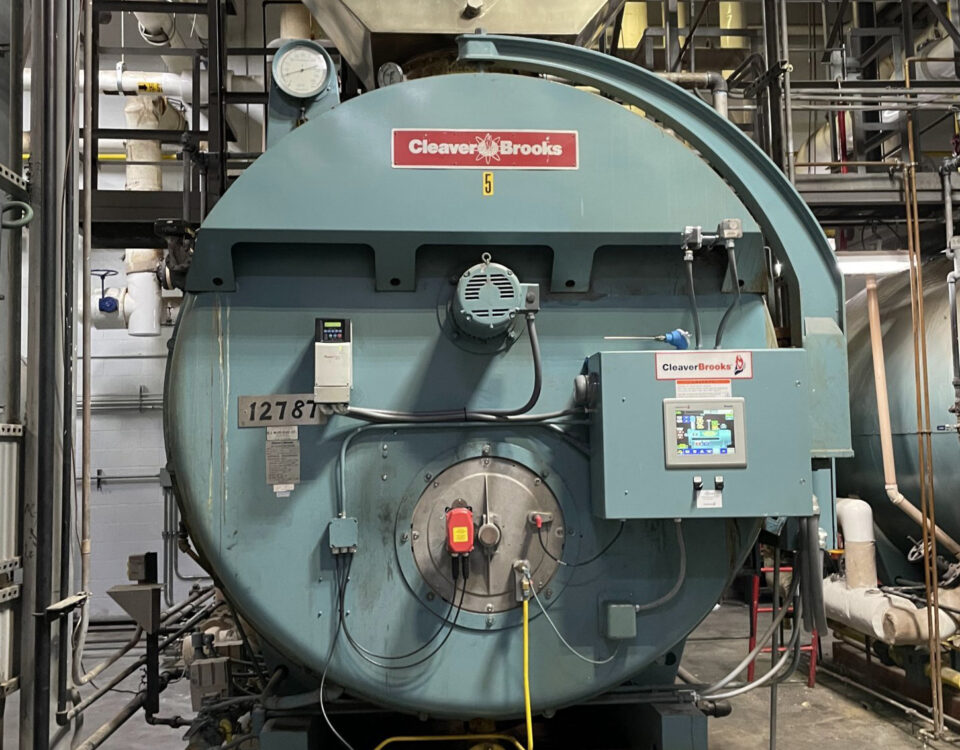

Cleaver-Brooks is considered one of the premier manufacturers with a full line of Electric boiler solutions. B.J. Muirhead is the authorized Cleaver-Brooks Representative across New York and areas of Pennsylvania. As a total boiler room solutions provider, we can supply and support Cleaver-Brooks equipment.

So let’s take a look at the Cleaver-Brooks Electric line of steam and hot water generators – starting with the Emersion type.

Immersion Steam & Hot Water Boilers

Model CR Electric Boiler

These Cleaver-Brooks Immersion Electric boilers are for smaller steam and hot water applications, and all include a cylindrical pressure vessel which can be either vertically or horizontally oriented, containing the Immersion elements. The upper part of the chamber is void of water thereby forming the steam space in the case of steam boilers, and is completely flooded in the case of hot water boilers.

Depending on the design pressure, the boiler will be constructed under either Section IV (low-pressure steam and hot water) or Section I (high-pressure steam) of the ASME Code. These packages will also carry the UL listing for enhancing safety and will be mounted on an integral steel frame and will be covered with a preformed, sectional steel painted jacket. The pressure vessel will also include hand holes and manways for inspection and service.

Controls normally include a Manual Reset High-Pressure Cutoff, Primary Low Water Cutoff with pump control, sight gauge, Auxillary. Low Water Cutoff, MR, feed water stop and check valves, blow down valves, and safety valve(s).

Electrically, the system load is controlled by either on/off stepping switches or automatic electronic proportioning (modulating) control; staging the respective immersion elements based on pressure fluctuations.

All of the electrical componentry is housed in a control panel(s) including contactors, transformer(s), stepping switches, fuses, terminal strip, and indicating lights.

C-B Immersion Electric Boiler Models

Model CR Vertical Steam boiler with a range of 12-563 kW and generating up to 1969#/HR with design pressures of 15, 150,200 & 250 Psig. Voltages up to 600V.

Model HSB Electric Boiler

Model S Vertical Steam boiler with a range of 12-2250 kW and generating up to 7875#HR with design pressures of 15,150,200 & 250 Psig. Voltages up to 600V.

Model HSB Horizontal Steam boiler with a range of 1560-3375 kW and generating up to 11,813#/HR with design pressures of 15,150,200 & 250 Psig. Voltages up to 600V.

Model WB Vertical Hot Water boiler with a range of 12-3360 kW and generating up to 11.5 MM Btu/HR with design pressures of 160, 200 & 250 Psig. Note the 200-250# boilers are built to ASME Section I (high pressure) requirements. Voltages up to 600V.

Electrode Type

Like the Immersion type, the Electrode Steam boiler package consists of an ASME-built pressure vessel mounted on a supporting base. The unit contains a central column from which water, under pressure, is forced through nozzles toward a neutral and several opposite phase alternating current electrodes that surround the central column. Steam is generated from the resistive flow of current through this water.

Electrode Boiler

The package includes an integrated pump and a control sleeve that moves up and down the column based on load demand and steam requirements. The pressure vessel tank is insulated and covered with a removable metal casing.

These boilers include a manway(s) for visual and manual adjustment of stream shape to match the load requirement. They will also include a standby electric heater installed in the tank to maintain pressure during the off-cycle, and a proportioning feedwater regulator that operates based on the signal from the level control mounted on the boiler in conjunction with the solid-state modulating pressure control.

The system package typically includes a conductivity control and sample cooler assembly to ensure proper water chemistry, avoiding electrode scaling which can hinder heat transfer. These conductivity controllers have adjustable high and low setpoints. Upon high setpoint actuation, automatic boiler bleed (surface blowdown) begins, usually indicated by a light. Low conductivity closes a PLC contact, potentially signaling a chemical feed pump to start.

All controls, switches, terminal strips, etc., are housed in a convenient pre-wired control panel with indicating lights. A sample cooler assembly is often supplied, including connections in the pressure vessel for boiler water sampling.

Typical boiler trim for these packages includes pressure gauges, water column and gauge glass, blowdown valves, safety valves, and a backpressure regulating valve used to throttle or close when boiler steam pressure drops below operating pressure, protecting the boiler against sudden system pressure drops.

C-B Electrode Specs

The Electrode Boiler has a fast response to load, a vertical high voltage jet-type design with design pressures ranging from 100-450 psig, an input range of 1-102 MW, and generating up to 340,000 pounds per hour. Power applied ranges from 4.16-25 kV.

As a specifying engineer, design/build contractor, or end user, you have several choices when evaluating and selecting the best boiler fit for your application. We hope you will consider the environmental and product benefits of electric boilers.

B.J. Muirhead can evaluate your boiler room to determine if your application is ideal for emissions-free electric boilers.